This summer promises to be a hot and heavy one, with all eyes laser-focused on “Green Run” testing of the Space Launch System (SLS) core stage at NASA’s Stennis Space Center in Bay St. Louis, Miss. Three of the eight key milestones have already been completed in the B-2 Test Stand, with a full-flight-duration static-firing of the four RS-25 engines for Artemis-1—the first flight of a human-rated spacecraft to lunar distance since Apollo 17—anticipated later this fall. Hopes remain high that Artemis-1 may fly its uncrewed mission around the Moon towards the end of 2021, but much attention is also riveted upon Artemis-2, a voyage to transport the first humans across the vast gulf of cislunar space since December 1972. And Aerojet Rocketdyne recently announced that it has completed its share of the propulsive muscle that will get Artemis-2 to the Moon.

“These are very exciting times for both NASA and the nation,” said Eileen Drake, Aerojet Rocketdyne president and CEO. “The United States is sending humans beyond low-Earth orbit for the first time in nearly 50 years and we are traveling even farther with Artemis than we did with Apollo.”

All told, the El Segundo, Calif.-headquartered firm is providing over two dozen different engines and motors for Artemis-2, most visibly four RS-25 main engines which will be mounted at the base of the SLS core stage. Drawn from their earlier heritage as the long-serving Space Shuttle Main Engine (SSME)—which powered 135 launches of orbiters Columbia, Challenger, Discovery, Atlantis and Endeavour from April 1981 through July 2011—the liquid oxygen/hydrogen-fueled RS-25 is over a half-century old. During the shuttle era, it achieved an estimated 99.95-percent success rate and was significantly upgraded over the years, although it did suffer several on-the-pad shutdowns and one high-altitude abort. Following a decision in 2011 to build SLS, the RS-25 quickly carved a niche for itself as part of the new rocket’s main propulsion system.

Artemis-2 will benefit from four members of a stockpile of 16 shuttle-era “heritage” RS-25s, which have been extensively modified to increase their maximum thrust from 491,000 pounds (222,700 kg) to as much as 512,000 pounds (232,200 kg). Efforts to ready the RS-25s for the Artemis-2 flight have been ongoing for several years.

In February 2018, Aerojet Rocketdyne completed a series of “hot-fire” tests of the Honeywell-made engine controllers for the mission, which are 50 pounds (23 kg) lighter and carry 20 times greater processing power than their shuttle-era predecessors. This makes them far more responsive to vehicle commands. Design simplifications and “additive manufacturing” methodologies also reduced the cost of building future RS-25s by up to 30 percent, as Aerojet Rocketdyne transitions from a once-reusable engine to a disposable one. Full acceptance-testing of all RS-25 engines for Artemis-2 was completed in April 2019.

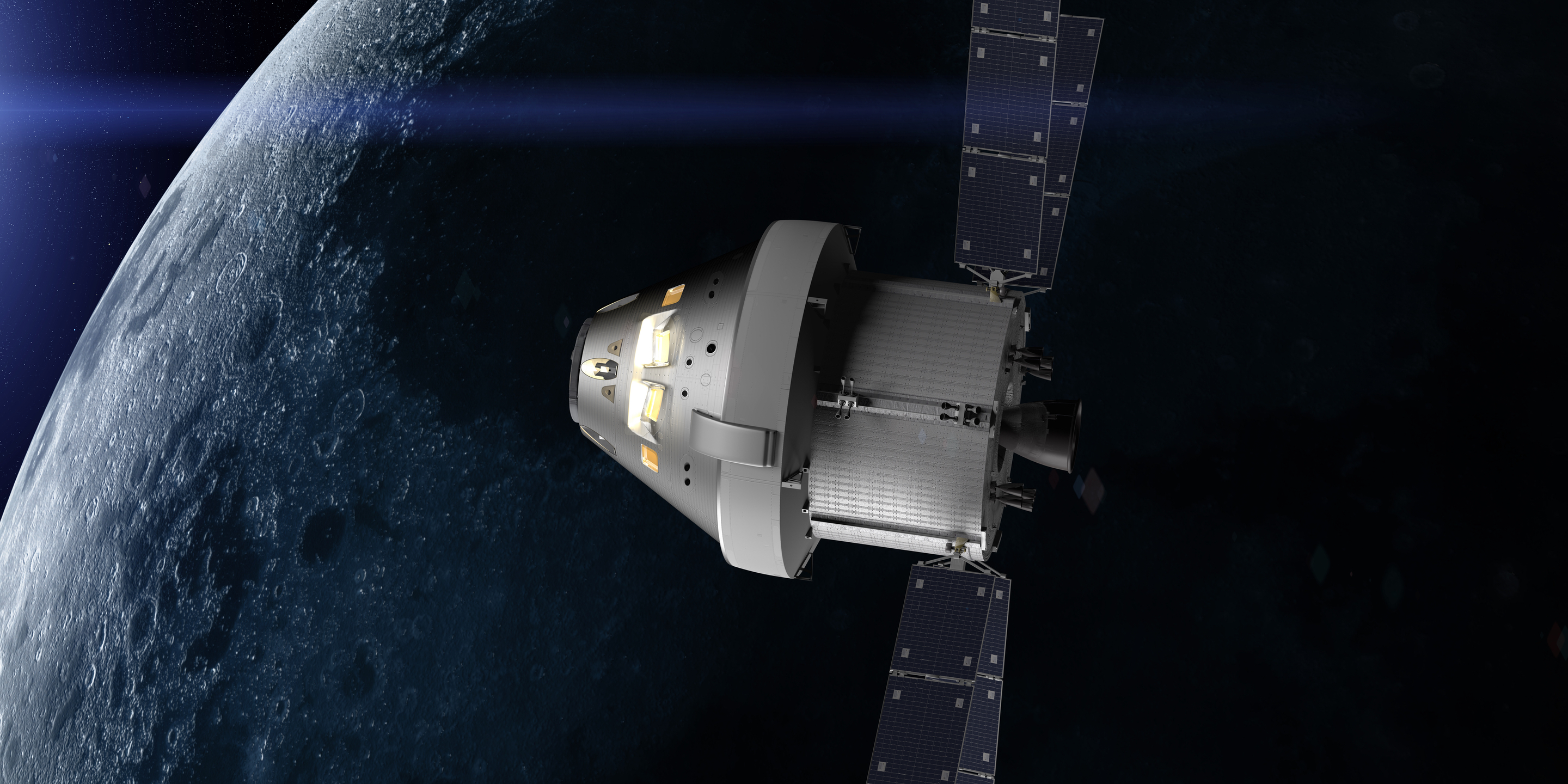

Although the four RS-25s will burn for approximately 8.5 minutes of the SLS ascent, Aerojet Rocketdyne’s facility in West Palm Beach, Fla., has also furnished the RL-10 engine for the Interim Cryogenic Propulsion Stage (ICPS), which will push the Orion Crew Module (CM) and European Service Module (ESM) for Artemis-2 to velocities above 24,500 mph (39,400 km/h) needed to reach the Moon.

Capable of producing 24,800 pounds (11,250 kg) of thrust, the liquid oxygen/hydrogen-fueled RL-10 for Artemis-2 was delivered to NASA-Stennis last February and will play a crucial role in helping SLS to deliver 57,300 pounds (26,000 kg) of payload to lunar distance. Final qualification of the engine and its integration into the ICPS is slated to be completed later this year.

Aerojet Rocketdyne has also provided the solid-fueled Jettison Motor (JM) for Orion’s Launch Abort System (LAS). Its 40,000 pounds (18,150 kg) of thrust carries the potential to support two very different mission possibilities. During a “nominal” ascent, it will separate the LAS from Orion right on the edge of space, enabling the crew to continue on their mission. But in the event of a launch anomaly, it will also afford a means to separate the LAS from Orion to allow the astronauts to execute a parachute-assisted landing.

The JM completed Critical Design Review (CDR) in late 2015 and completed tests at Aerojet Rocketdyne’s facility in Rancho Cordova, Calif., in the summer of the following year. Although there are two other abort motors aboard the LAS, the reliability of the JM is particularly paramount, as it is alone among them in that it must function perfectly both on a nominal ascent and during an abort. “Unlike the other launch abort system motors,” said Jim Paulsen, vice president of NASA programs at Aerojet Rocketdyne, “the jettison motor operates every time.”

In July of last year, the JM was definitively put through its paces on the Orion Ascent Abort-2 (AA-2) test, conducted atop a refurbished Peacekeeper intercontinental ballistic missile solid rocket motor, out of Cape Canaveral Air Force Station, Fla. Launched to an altitude of more than 31,000 feet (9,450 meters) and attaining velocities in excess of 1,000 mph (1,600 km/h), the abort sequence was triggered and all three abort motors (including the JM) performed their tasks to perfection. After final qualification trials at Redstone Arsenal in Huntsville, Ala., assembly of the JM for Artemis-2 was completed in Orange, Va., before being delivered to Lockheed Martin for testing in February 2020.

If powering the SLS core, ICPS upper stage and abort system was not enough, Aerojet Rocketdyne is also supplying propulsion elements for the Orion CM and ESM. The Orion Main Engine (OME)—a singular AJ-10, powered by monomethyl hydrazine and nitrogen tetroxide—owes its design heritage to the Orbital Maneuvering System (OMS) used for 30 years for orbital insertion, deorbit and major maneuvers during the shuttle era. Capable of generating 6,000 pounds (2,700 kg) of thrust and will provide Orion’s main capability for in-space manueuvering. According to Aerojet Rocketdyne, “key valve and thermal components” for the Artemis-2 OME were provided to NASA in March 2019 to complete the refurbishment of the engine.

During flight, the OME sits on the aft section of the ESM, surrounded by eight Auxiliary Engines in four pairs, which will offer positioning control, as well as backup maneuvering capability. And by providing off-pulsing for steering and redundancy for the OME, they are expected to greatly enhance crew safety. Based in design upon Aerojet Rocketdyne’s highly reliable R-4D engine and built in Redmond, Wash., each one produces 110 pounds (50 kg) of thrust. It was put through initial hot-fire acceptance testing in March 2017 and in June of last year the Auxiliary Engines for Artemis-2 were delivered for integration into the ESM.

Finally, Aerojet Rocketdyne has furnished 12 Reaction Control System (RCS) motors, which will occupy pod assemblies around the circumference of the Orion CM. Based in design upon the MR-104J engine, each hydrazine-fed motor has a thrust of 160 pounds (73 kg) and is designed to control the spacecraft’s orientation during atmospheric re-entry and alter its course in readiness for splashdown in the ocean.

Together with the JM, the RCS completed its CDR phase in October 2015 and, right from the outset, was notable in that it contained Orion’s first additively-manufactured components, in the form of engine nozzle extensions. “The Reaction Control System on the Orion Crew Module is critical for astronaut crew safety,” said Julie Van Kleeck, vice president of Advanced Space & Launch Programs at Aerojet Rocketdyne, “which is why we have invested heavily in the development and testing of additively-manufactured components.”

Just last December, Aerojet Rocketdyne was also awarded a contract by Lockheed Martin to support production of Orion missions for Artemis-3 through Artemis-5, with an option to continue through Artemis-8. Many of the objectives of these missions remain undefined at present, although Artemis-3 is currently envisaged to see the next man and the first woman set foot on the surface of the Lunar South Pole in 2024. Its successors are expected to support the delivery and activation of hardware for the Lunar Gateway.

FOLLOW AmericaSpace on Facebook and Twitter!

Missions » SLS » Artemis »