For more than three decades NASA’s space shuttle fleet was looked after in three separate Orbiter Processing Facilities, or OPFs, at the agency’s Kennedy Space Center launch site in Florida. Now, with the shuttle program a fading memory, one of these “excess government buildings” is being converted into a next-generation commercial facility for Boeing to build their CST-100 spacecraft, and the company recently finalized a deal with Space Florida to do just that.

Space Florida, a state-funded aerospace economic development agency, came to an agreement with NASA in late 2011 to take over the use of the facility. Space Florida, in turn, is leasing the building to Boeing for their CST-100 processing, along with the shuttle main engine processing facility. The alternative, being that NASA no longer has a reason to use the facility or the funding to maintain it, would have been to simply tear it down.

“It just makes sense that if we have facilities that we have absolutely no use for in NASA’s Space Launch System or Orion programs, we ought to be able to find a way to bring other work into those facilities,” said KSC Director Bob Cabana. “We are allowing Space Florida to have it for 15 years, at no cost to NASA.”

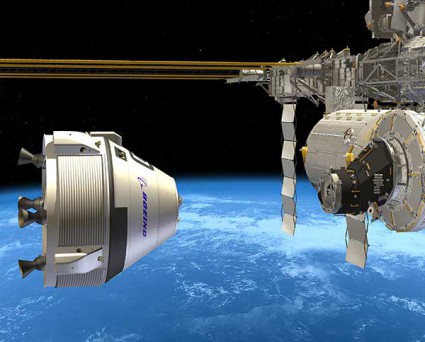

Boeing, in collaboration with NASA’s Commercial Crew Program (CCP), plans to begin building their CST-100 spacecraft next year, using the former OPF-3 as their new Commercial Crew and Cargo Processing Facility. The facility, now known as C3PF, has been going through major renovations over the past year to meet requirements for building the CST-100, which Boeing and NASA hope will eventually transport crews to low-Earth orbit and the International Space Station. Custom gantries, platforms, hydraulic systems, propellant servicing equipment, and other custom shuttle servicing equipment have been removed to transform the facility into a clean-floor, factory-like concept to support Boeing’s CST-100 development.

“With the removal of legacy Space Shuttle Program infrastructure, the building will be transformed into a clean factory system layout for spacecraft production and refurbishment,” said Chuck Hardison, Boeing’s manager of CST-100 Production and Ground Systems. “We’ll have defined factory positions to support different phases of the spacecraft being built.”

Boeing hopes to have their spacecraft ready to fly an initial three-day crewed orbital test flight in 2016, with the first mission to the ISS following in 2017—assuming funding and development contracts all go as planned. Support equipment, tooling, and control systems that will be needed for the production and manufacturing phases are already under development (and have been for some time). Manufacture, assembly, testing, and operation of CST-100 will all take place at the Florida launch site, which will put around 550 uniquely skilled engineers and technicians back to work on the Space Coast.

“We expect it to be a very bustling place at full operations,” Hardison said. “When we’re in the full operational services phase, we expect to see a large increase in the number of people working here.”

The battery-powered CST-100 spacecraft is expected to launch a crew of up to seven atop a United Launch Alliance (ULA) Atlas-V rocket from Space Launch Complex-41 at nearby Cape Canaveral Air Force Station, which is a little more than seven miles away from C3PF. Although the Atlas-V is the choice for the first launch, the spacecraft itself will be compatible with multiple launch vehicles, such as the ULA Delta-IV and SpaceX Falcon-9 rockets. The CST-100 will be covered by a protective container and transported to the launch pad atop a KMAG transporter, much like NASA’s satellites are taken to their launch vehicles prior to launch.

Boeing is one of several companies, including SpaceX and Sierra Nevada, working with NASA’s Commercial Crew Program to provide safer and cheaper crew transport to and from the ISS and other low-Earth orbit destinations—such as the proposed Bigelow Aerospace Commercial Space Station. With the retirement of NASA’s space shuttle fleet in 2011, the United States does not currently have a spacecraft to replace them, and until a spacecraft is ready NASA is currently forced to buy seats on the Russian Soyuz—at some $71 million per seat.

Several drop tests have already been conducted with CST-100 test articles in both 2011 and 2012, and astronauts Serena Aunon and Randy Bresnik recently spent a full day evaluating communications, ergonomics, and crew-interface aspects inside a full-scale mockup of the spacecraft, showing how future crews will operate in the CST-100. Boeing took the opportunity to see what works well and what needs modifications before fixing the final capsule design for construction, gauging an astronaut’s ability to work in the seats and move around during hands on use of the equipment, display consoles, and storage compartments.

This past August the company also conducted an interface test between the Mission Control Center (MCC) at NASA’s Johnson Space Center in Houston and the software planned for CST-100, verifying that Boeing could send and receive data from its Avionics Software Integration Facility to the MCC. Boeing’s software facility and CST-100 spacecraft simulator are serving as precursors to integrated flight operations training.

Test firings of the spacecraft’s steering jets were conducted at White Sands Space Harbor in Las Cruces, N.M., last month. The orbital maneuvering and attitude control system, or OMAC system, which is made up of 24 thrusters, was fired in a vacuum chamber to evaluate performance in a space-like environment at 100,000 feet in altitude.

Boeing is on track to meet all 20 of its Commercial Crew integrated Capabilities (CCiCap) milestones by the summer of 2014. Ten have already been completed, and another six are expected to be completed before the end of this year.

Want to keep up-to-date with all things space? Be sure to “Like” AmericaSpace on Facebook and follow us on Twitter: @AmericaSpace

Hi

that was one good article! http://www.functionalfoot.com/gucci-belts-on-sale.html http://www.functionalfoot.com/gucci-belts-on-sale.html