BALLY, PA, and KENNEDY SPACE CENTER, FL — What did NASA and Orion prime contractor Lockheed Martin learn from the maiden test flight of the agency’s next generation crew vehicle, following its recent successful launch in December 2014 and homecoming return to the Kennedy Space Center?

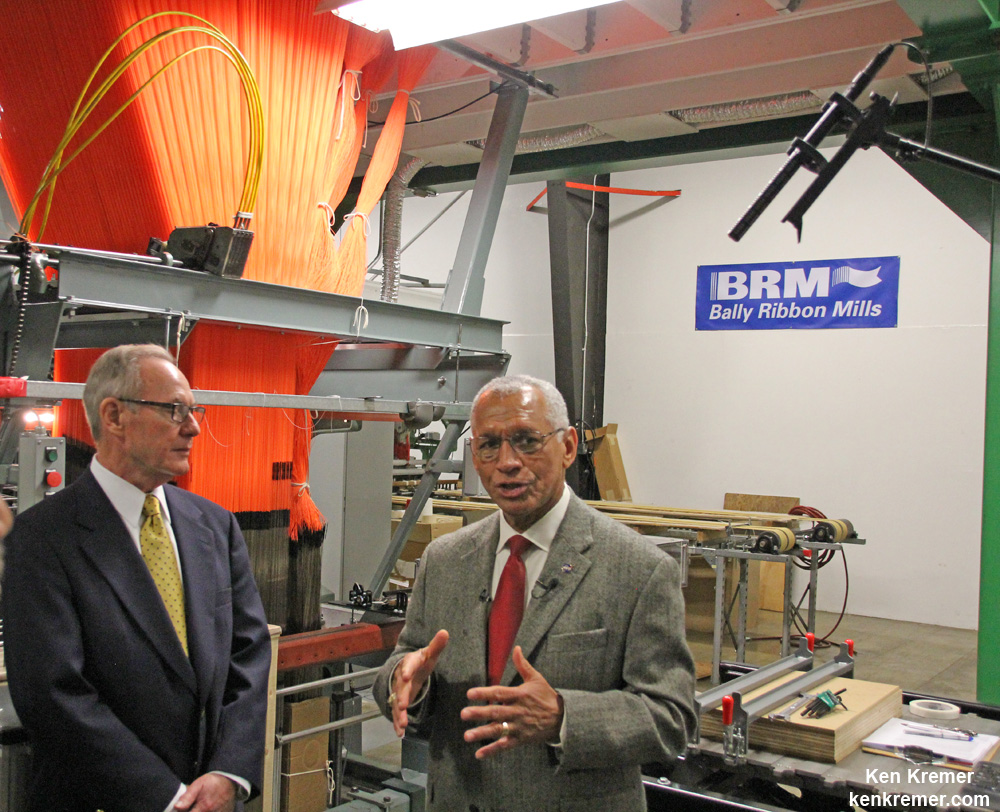

“Orion is in incredible shape!” NASA Administrator Charles Bolden told AmericaSpace during an interview at Bally Ribbon Mills in Bally, Penn., on Jan. 9. “It gives a lot of confidence [for the future].”

Although a full analysis of Orion’s first flight is still underway, the initial look is promising.

“The flight was almost flawless,” Bolden said.

But there are always lessons to be learned and things that can be changed or improved. That’s why test flights are conducted and that’s what AmericaSpace discussed with Bolden at Bally.

Bally Ribbon Mills is a small company, led by President Ray Harries, that will provide critical 3-D woven thermal protection components for NASA’s new Orion crew capsule, currently under development and that will one day take our astronauts on deep space journeys farther than ever before. Robust thermal protection is essential to saving the crew lives during atmospheric reentry upon returning home.

“It’s all aimed at getting NASA to Mars,” said Bolden. “We cannot get to Mars without the type of material that’s being developed here at Bally.”

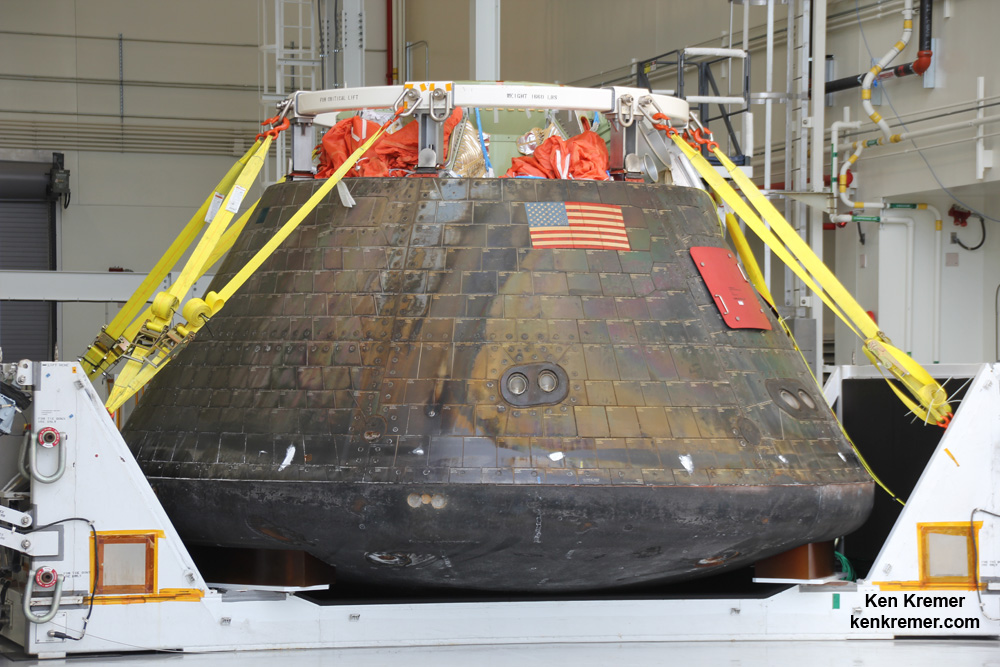

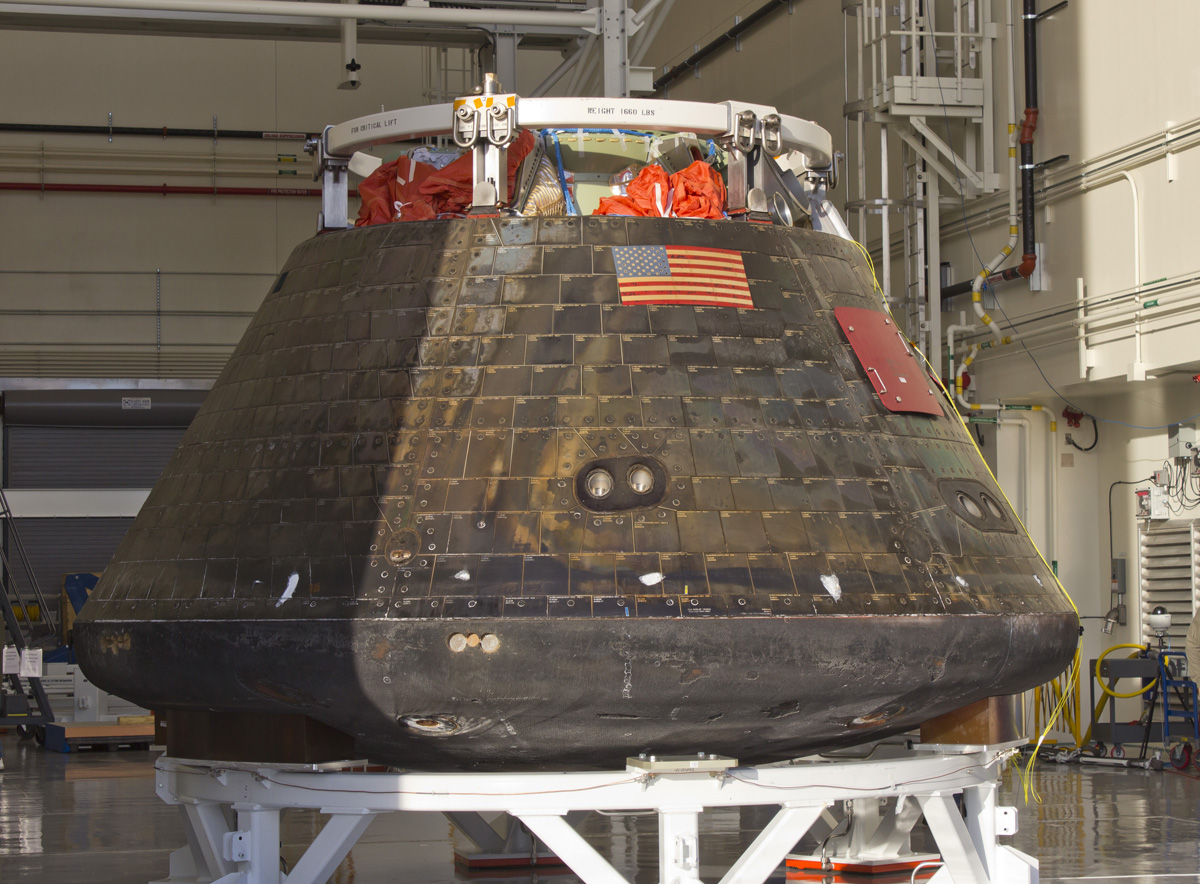

NASA’s first flight-worthy Orion capsule just flew to space and back during its inaugural test flight on the Exploration Flight Test-1 (EFT-1) mission barely a month ago.

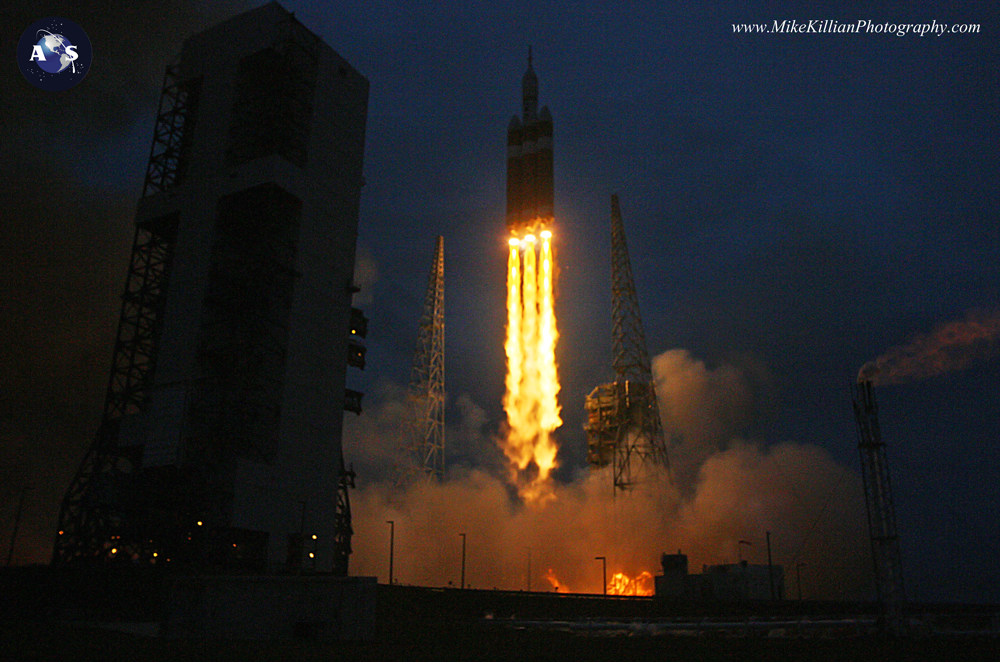

Orion EFT-1 roared to space with a picture perfect launch on Dec. 5, 2014, atop the 242-foot-tall United Launch Alliance Delta IV Heavy rocket—the world’s most powerful booster—at 7:05 a.m. EST from Space Launch Complex 37 (SLC-37) at Cape Canaveral Air Force Station in Florida.

NASA Administrator Bolden and Mike Hawes, Lockheed Martin Vice President & Program manager for Orion, were visiting Bally to learn firsthand about some changes that will be made to the heat shield for Orion’s next flight in 2018 on the Exploration Mission-1 (EM-1), based on lessons learned from the EFT-1 flight. Lockheed Martin is the prime contractor for Orion.

Bolden had also just visited the Orion EFT-1 capsule at the Kennedy Space Center (KSC) in Florida for the first time following its mission ending splashdown in the Pacific Ocean, recovery, and cross country trek back to the Florida launch site.

What did you learn when you saw the returned vehicle at KSC on Jan. 6? What did NASA learn from Orion? This writer asked Bolden.

“We are still learning what we learned from the flight,” Bolden replied.

“So we found several things,” Bolden elaborated. “One, the vehicle when I looked at it was in incredible shape!”

The Delta IV Heavy boosted Orion on a two-orbit, 4.5-hour flight that carried the EFT-1 capsule to an altitude of 3,604 miles. During Orion’s high speed atmospheric reentry, it approached speeds of 20,000 mph (32,000 kph) or about 85 percent of the reentry velocity for astronauts returning from journeys to deep space destinations like the Moon, asteroids, and Mars.

It endured scorching temperatures near 4,000 degrees Fahrenheit (2200 C) to test the 16.5-foot-wide heat shield and thermal protection tiles during the 10-minute descent.

What did you expect? What were the results from EFT-1? How well did the heat shield perform?

“So if you asked me what I expected to see from a vehicle that had been 3600 miles out and came back in at 4000 degrees F and had what is called an ablative coating on the bottom of it – that’s the part that is supposed to burn off. Well it didn’t burn off!” Bolden responded.

“The heat shield was in incredible shape. An Apollo spacecraft would not have looked like that.”

“And so we are learning a lot of things. Like on fuel usage.”

“On the navigation system we were only single string. This wasn’t a full up Orion.”

“But we found the flight in itself was almost flawless.”

“Now that doesn’t mean that every flight is going to go like that. But it sure does give the team a feeling of confidence that we had a pretty good idea of what we were doing.”

“Some things were much better.”

Regarding the fuel usage, the EFT-1 capsule only used about one third of the hydrazine maneuvering propellant loaded on board.

“The capsule used only about 90 pounds of its about 300 pounds of hydrazine propellant stored on board,” Jules Schneider, Orion Project Manager for Lockheed Martin, told AmericaSpace during an interview at the Dec. 19, 2014, homecoming event at KSC.

“All of the separation events went beautifully and basically required virtually no maneuvering fuel to control the attitude of the capsule. The expected usage was perhaps about 150 pounds.”

“Therefore there was a lot more hydrazine fuel on board than we expected. And we had to be cautious in transporting Orion across the country.”

“The heat shield performed very well. I don’t know if you can tell, we’ve actually taken a few core samples off the heat shield already and we’re looking at those,” Schneider added. “We will be removing the heat shield from this vehicle later in February so we will get an ever better look at it.”

What are the lessons learned for the future for NASA and Lockheed?

“Mike Hawes, from Lockheed Martin, and I were just discussing this,” Bolden replied.

“So what we hope to do right now is have a NASA and Lockheed Martin partner team [prime contractor] get together. And we’ll say, OK what have we learned.”

“What are some things that we had planned to do in the future, are things that we may not need to do now.”

“What tests are there that we were going to do? And maybe instead of doing three evolutions of that test, instead maybe we can get away with just one test.”

“Also, what things surprised us? And maybe we need another test.”

“So we are still going through all that. It will probably still be weeks or months before we have definitive answers on all that.”

From Lockheed Martin’s perspective, what was learned from EFT-1? Have technicians taken it apart yet and looked inside yet? This writer asked Lockheed VP Mike Hawes.

“So far in the quick look stuff in everything we gave to NASA everything looked really good,” Hawes replied.

“The capsule is back in Florida. The back shell panels are mostly off. So some of the systems that did have some issues like in operating systems, the guys can now actually crawl around and actually see what is going on.”

“So we are looking thoughtfully at how much we can pull out [for the next flight on EM-1].”

“We have delivered all the high speed data to NASA. So NASA and our guys are going through all that.”

“So far the quick looks were mostly based on operational telemetry that we got in real time during the mission.”

“And things like the video that NASA released, where we see the plasma actually form out the top hatch window was phenomenal,” Hawes explained.

For its deep space missions, Orion has been designed to launch atop NASA’s mammoth Space Launch System (SLS) rocket, concurrently under development.

Orion’s next flight during the EM-1 mission is currently scheduled for 2018 atop the first launch of the SLS.

“I’m extremely proud of the team,” Bolden remarked when he visited the EFT-1 capsule at KSC on Jan. 6. “Spaceflight is hard.”

“Orion is the vehicle that will get us on our way to Mars, asteroids and other places. It is an incredible vehicle and it came through pretty well.”

“Stay excited. EFT-1 was just the first Orion. The team is getting the vehicle ready for the Ascent Abort-2 test. We have things we have to tick off. This is the future and we are going to make it good.”

“We learn something every single time we fly. If we are not learning, then we’re not doing something right.”

Bally’s role on EM-1 is to provide the compression pads that fill in the joints on the heat shield between the Orion crew module and the service module.

Watch for details about Bally’s work on the compression pads in a new story for AmericaSpace.

And be sure to read the story about the re-flight of the EFT-1 capsule on the Ascent Abort-2 (AA-2) mission here.

It’s due to launch atop a Peacekeeper missile from Space Launch Complex 46 (SLC-46) at Cape Canaveral Air Force Station.

Stay tuned here for continuing updates on Orion, commercial crew, and more.

Want to keep up-to-date with all things space? Be sure to “Like” AmericaSpace on Facebook and follow us on Twitter: @AmericaSpace

Great article Ken,

If there are more similar interview opportunities in the future, I’d love to hear about what went on with the uprighting bags, as well as why they’d opt to not drain the hydrazine as a part of the safing procedures before transport.

Thanks Tim! Watch for Part 2 soon with more on Orion and answers to these and other points