The James Webb Space Telescope (JWST), a NASA collaboration with the European Space Agency (ESA) and the Canadian Space Agency (CSA), continues to take shape in a 1.3 million-cubic-foot clean room as engineers at NASA’s Goddard Space Flight Center in Greenbelt, Md., continue putting together what is being billed as “Hubble’s successor” for a planned late 2018 launch.

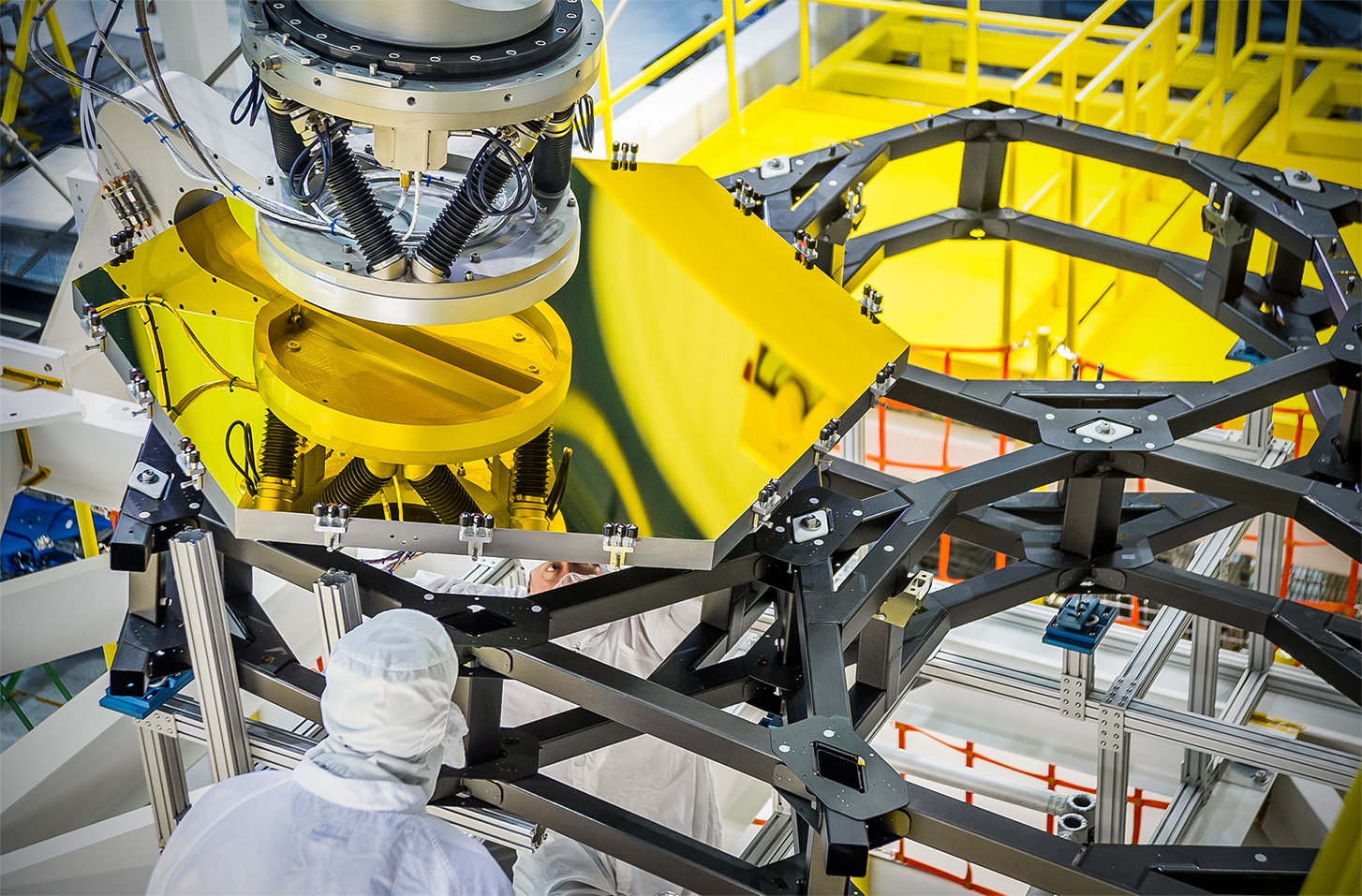

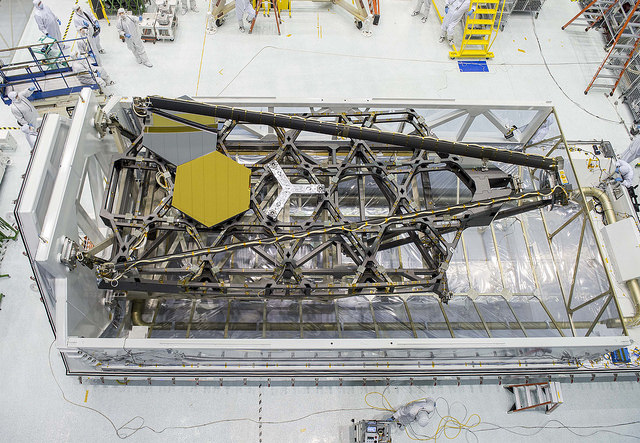

The telescope is being primed to receive all 18 of its primary flight mirrors. In addition, the “wings” of the backplane structure, which will carry those mirrors, were deployed, while the mirrors themselves were measured with precision to ensure they will be a perfect fit. Concurrently, the Integrated Science Instrument Module (ISIM), characterized as the scientific “heart” of JWST, is undergoing its final “super cold” test inside a thermal vacuum chamber, simulating the harsh conditions it will encounter 1 million miles (1.5 million kilometers) from the ground.

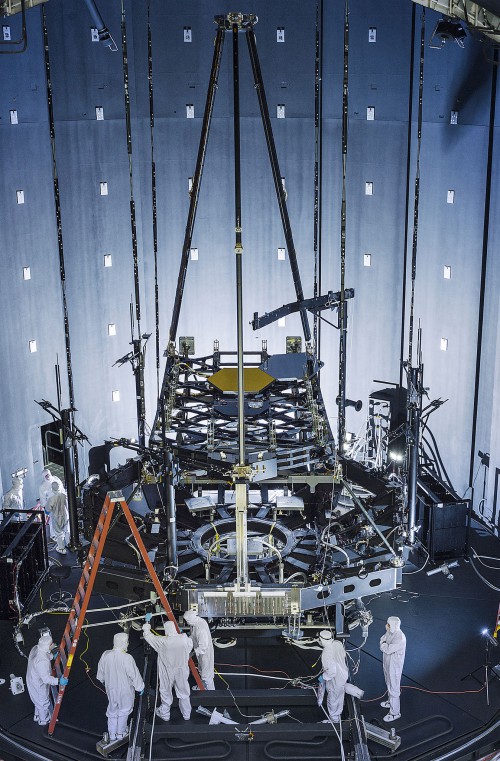

Backplane Structure Being Readied For Mirror Segments

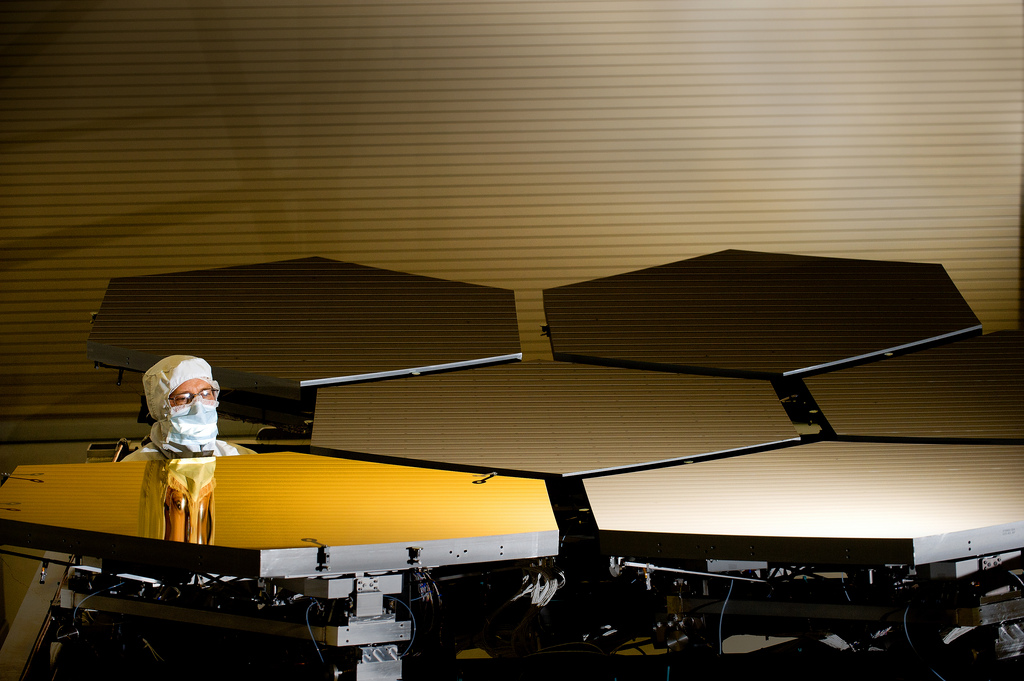

NASA announced on Wednesday, Nov. 18 that the JWST telescope structure was lifted into an optical stand, with the structure being readied to receive all 18 of the telescope’s hexagonal, gold-coated mirrors (the mirrors themselves are made of beryllium). Days earlier it was announced that the telescope’s two “wings,” the side portions of the backplane structure, were deployed twice with success.

“We deploy the wings one at a time. Each individual deployment can take up to 16 hours or more to complete,” said Adam Carpenter, Mechanical Integration Engineer at Goddard, as he and other engineers prepared for the move. “It is a delicate operation requiring multiple groups to perform specific tasks. The two wings of the telescope structure will eventually hold 6 of Webb’s 18 primary mirror segment assemblies.”

These wings will be folded inside the fairing of an Ariane 5 launch vehicle for its projected October 2018 launch from Europe’s Spaceport in Kourou, French Guiana; as the telescope cannot be serviced following its launch (unlike the Hubble Space Telescope or HST, which was serviced five times in low-Earth orbit by space shuttle crews between 1993 and 2009), these components’ successful deployment in space is vital to the mission’s success.

NASA also divulged that Goddard engineers were also recently performing “mirror metrology,” described as “ultra-high accuracy measurements,” to ensure the next-generation mirrors are a perfect fit in the telescope’s structure.

“The complexity of the mirror assemblies comes from the fact that they are designed to be very lightweight, work at cryogenic temperatures below -400F, survive launch vibration and forces, be align-able on-orbit via actuators, and then stay aligned for up to two weeks as though they are a single large mirror,” said Lee Feinberg, NASA Optical Telescope Element Manager for the James Webb Space Telescope at the Goddard Space Flight Center in Greenbelt, Md.

Putting Webb into position for its observations is one thing, but getting the giant segmented mirror to focus on galaxies millions, even billions, of light-years away is another challenge all together. In order to ensure Webb achieves a single perfect focus, engineers will use six tiny mechanical motors, or actuators, attached to the back of each mirror piece to capture the images they expect Webb to produce.

“Aligning the primary mirror segments as though they are a single large mirror means each mirror is aligned to 1/10,000th the thickness of a human hair,” says Feinberg. “What’s even more amazing is that the engineers and scientists working on the Webb telescope literally had to invent how to do this.”

Photo Credit and Caption: NASA/Chris Gunn

Another problem with “traditional” telescope mirrors is the fact that they are heavy. If Webb’s mirror was made same as the Hubble, then it simply could not be launched. To get around this, Northrop Grumman (the company that is leading the effort to build Webb) decided to make Webb’s mirrors from Beryllium, which is a very strong but light metal. In order for the telescope’s instruments to function properly, the observatory also needs to be kept very cold, -400 degrees Fahrenheit cold, and Beryllium holds its shape at those cryogenic temperatures and is a good conductor of electricity and heat.

Gold coats the finished mirrors and is used to improve the mirror’s reflection of infrared light.

The process of mounting JWST’s first flight mirror will occur this weekend, you can watch a live stream video from the Goddard clean room HERE.

While the telescope itself begins to come together on course for its launch, a previous AmericaSpace article discussed how JWST’s “pathfinder” test article was recently put through a cryogenics optics test.

As mentioned before, JWST cannot be serviced once in space; lessons learned from Hubble are still fresh. The real thing must function perfectly post-launch (especially at 1 million miles out from Earth, the second Lagrangian point, or L2). In addition, the telescope will be exposed to extreme conditions, which can stress any spacecraft. The side in shadow will face temperatures of -400 degrees Fahrenheit (-240 degrees Celsius). In stark contrast, the other side of the telescope must be shielded from the Sun’s light and heat by a tennis-court sized sunshield comprised of five layers.

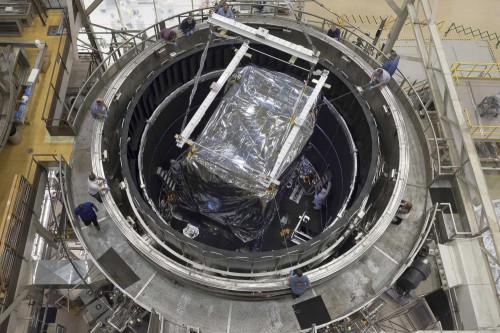

The article stated: “The goal of the Pathfinder tests is to thoroughly check the replica mirror segments in the cryogenic conditions that the flight ones will operate under when the telescope is deployed following its arrival at the L2 Lagrange point. To that end, the JWST engineering teams have been in the process in recent years of revamping the famous cryo vacuum Chamber A at NASA’s Johnson Space Center in Houston, TX, which had previously been used for testing the Apollo spacecraft in the 1960s.” These tests will ensure that once the flight telescope is ready, it can be successfully tested, staying on target for a timely launch.

ISIM Enters Final Deep Freeze, Simulating Extreme Flight Conditions

While JWST’s optics continue to come together, in late October NASA announced that the telescope’s science instruments were entering their third and final cryogenic test inside Goddard’s Space Environment Simulator (SES), a giant thermal vacuum chamber. This test will again expose the ISIM to similar conditions it will encounter at L2, ensuring it will operate successfully during its mission.

Engineer Jack Marshall discussed the procedures taken during these “super cool” tests. “After we moved ISIM into the chamber, we close the lid. Then we pump air into the chamber, so we can continue to set up inside the chamber. Once everything is set, we pump out the air inside the chamber to create a vacuum. We then use liquid nitrogen and liquid helium to cool surfaces on the chamber walls and test structure, simulating the temperatures the telescope will see in space,” he related. This test will span several months, showing engineers how these components react to extreme cold and the vacuum of space; once successfully wrapped up, the ISIM can be integrated with the rest of the telescope.

According to NASA, the ISIM also recently underwent a successful acoustic test and an electromagnetic interference test.

*****

Three years prior to launch, buzz about JWST continues to grow. In an interview conducted for the 25th anniversary of HST in April, NASA astronaut James Newman discussed JWST: “…JWST is not a replacement, but a successor to HST, as it has its own distinct capabilities, seeing primarily in the infrared (IR). …Whenever we field a new sensor of any kind, and JWST certainly promises to have impressive sensing capabilities, we learn SO MUCH. There is no doubt in my mind that we will find tremendous surprises as well as expected results when we turn JWST on.”

When operational, JWST will be able to see the first galaxies forming approximately 13.5 billion years ago. NASA Goddard’s engineers and the telescope’s prime contractors at Northrop Grumman continue to ensure when October 2018 hits, JWST is ready to spread its wings and fly, bringing incredible images home.

Be sure to “Like” AmericaSpace on Facebook and follow us on Twitter: @AmericaSpace

.

.

Missions » James Webb Telescope »