XCOR Aerospace, a spacecraft and rocket engineering company, is developing a new spacecraft that will take paying customers to the edge of space. The exciting suborbital vehicle is taking shape and meeting critical milestones at the company’s Hangar 61 in Mojave, Calif. Starting with the mounting of the primary nose structure, the company has been busy performing fit checks and tests on the many important parts that make up the Lynx reusable launch vehicle.

Mounting the primary nose structure to the Lynx has been one of the most important milestones for the company. The nose will house several reaction control thrusters and the nose gear. They will soon attach the nose gear and install several of the nose gear actuation subsystems. In addition to the nose, there are several critical components to the Lynx structure: the fuselage, the wings and control surfaces, wing strakes, and the cockpit.

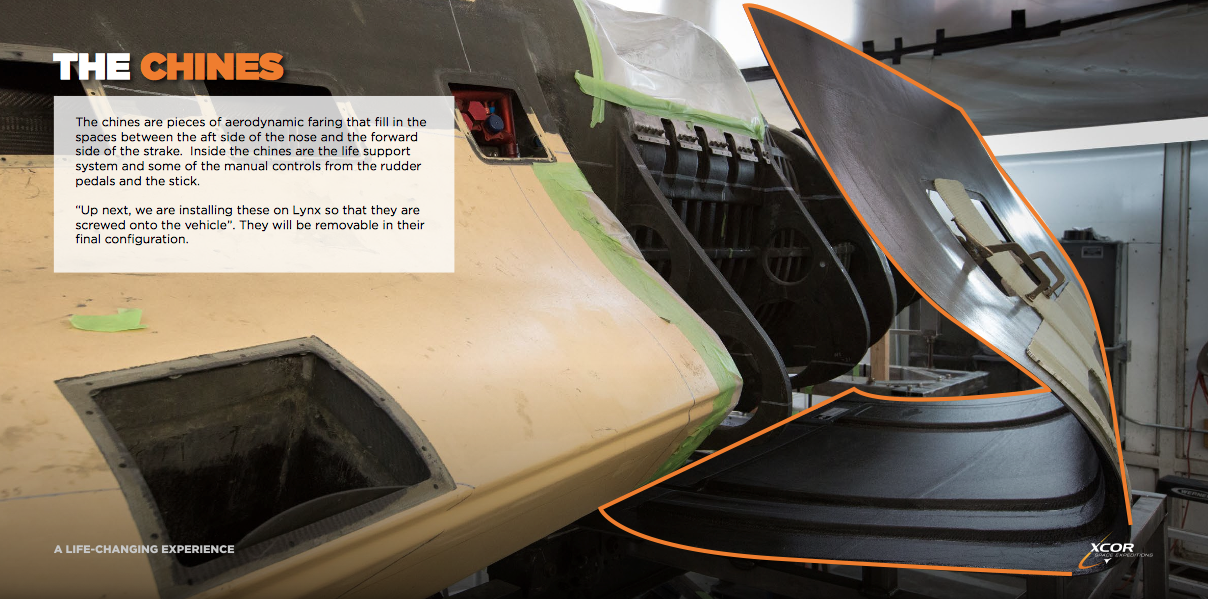

Fit checks of the chines and cowling have also been made. These recent fit checks are key milestones in the structural completion of the Lynx spacecraft.

The chines are pieces of aerodynamic faring that satiate the spaces between the backside of the nose and the forward side of the strake. The chines house some of the manual controls from the rudder pedals and the stick, as well as the life support system. The chines will be removable in their final configuration.

The cowling serves as a shield for the engine truss, pumps, and helium tanks. When the cowling is complete, it will be installed in an independent top and bottom half, and be removable. Access doors on the port (left) and starboard (right) sides of the structure will make possible to perform routine maintenance. The cowling will soon be trimmed to its final shape before being installed on the Lynx.

The Lynx landing gear is undergoing drop tests and will be mounted to the spacecraft sometime soon.

“We have to qualify the nose gear before we fly, and one of the ways we do it is with our drop test rig,” said Tony Busalacchi, a mechanical engineer at XCOR.

The landing gear strut is tested for its strength and stiffness by placing a number of weights on top of it. The strut is designed to resist compression and has many sensors analyzing the different forces working on it. In September, XCOR said their “next step is to modify the drop test rig to allow a full up test with flight loads, and then a little beyond flight loads so that XCOR achieves its margin of safety.”

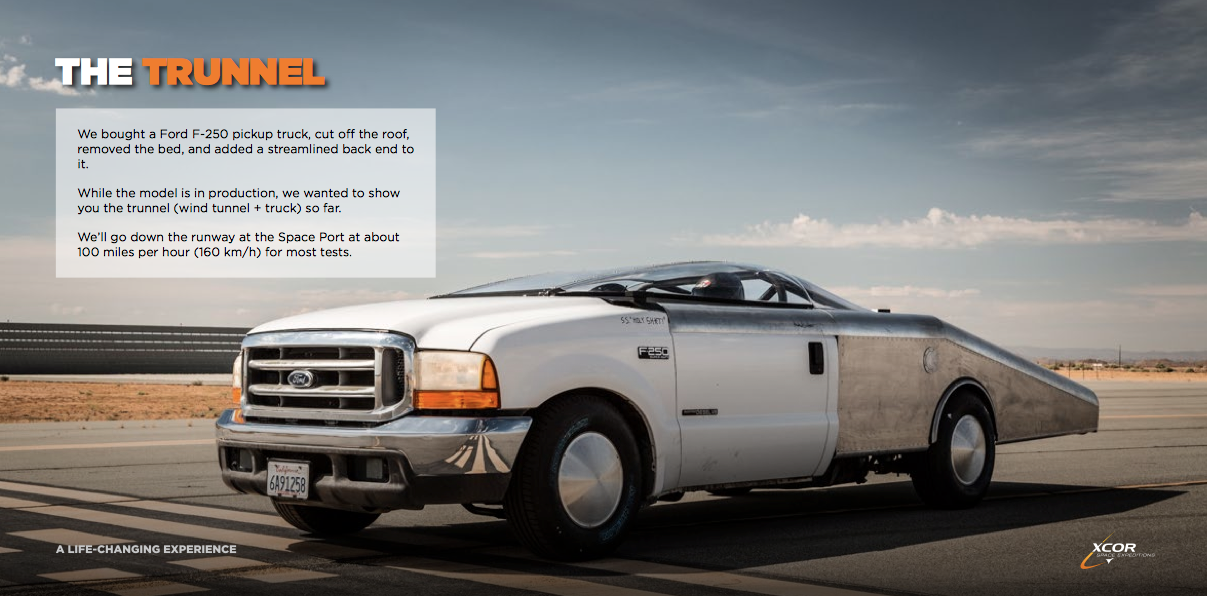

In an effort to be more cost-effective and efficient, XCOR decided to transform a standard pick up truck into an advanced test vehicle to measure the aerodynamic properties of different parts of the spacecraft. Instead of testing components inside a wind tunnel, the company is racing a pick up truck down the runway at the Mojave Air and Space Port at nearly 100 mph (160 km/h) for most of the tests. The Hangar 61 team cut off the roof, removed the bed, and added a streamlined back end to the Ford F-250 now known as the “trunnel” (truck + wind tunnel).

Tuft tests are taking place to help determine how the air flows over the area. Before placing a 1:3 Lynx scale model, red tuffs of yarn attached to a piece of plywood are tested first. This technique, known as tufting, is commonly used in aeronautics for flow visualization. Observing the tufts in motion can give clues to flow features.

The big question: When is the first test flight?

A previous AmericaSpace article from May notes that XCOR’s initial test flight vehicle, Lynx Mark I, is expected to begin a flight test program later this year. However, a letter from Harry van Hulten in XCOR’s October Mission Update emphasizes the importance of not rushing the production of the first experimental spacecraft.

“The fact is that we are in a process in which you just can’t rush things. For the first time in history we are developing a genuinely instantly reusable launch vehicle and there’s no building instructions, best practices or timeline available for something so ground breaking. Our engineers in Mojave have been developing each single component for the first time: from fuselage to the reusable engines, from pressure cabin to finally the wings which we’re building at this moment. Whilst doing so they have only one thing on top of their minds: safety. Cutting corners is not an option. Check, double check and then check again.”

Van Hulten is an XCOR Lynx test pilot with a military background. He never feared flying experimental aircraft in the military because he trusted the engineers, and he expects the same from the engineers at XCOR. Safety is the number one priority, so instead of providing a first flight date, those anxious to see Lynx fly for the first time will have to accept that “it’s ready when it’s ready.”

Founded in 1999, XCOR Aerospace has a 10,375-square-foot hangar on the Mojave Air and Space Port in California and a 60,000 square foot hangar at the Midland International Air and Space Port in Midland, Texas. The company has the XCOR Space Expeditions sales office in Amsterdam with a regional office for Asia in Hong Kong.

XCOR Space Expeditions, part of XCOR Aerospace, has a number of strategic partnerships with global brands such as KLM, Unilever, Luminox, Philips, Heineken, and most recently, Sinomax. The XCOR and Sinomax partnership was announced last month and will contribute to the customer’s flight experience by making it safer and more enjoyable.

XCOR will use Sinomax visco-elastic foam, most commonly known as “memory foam,” in every seat built for the Lynx spacecraft. The memory foam developed by Hong-Kong based Sinomax is able to offset the 4G forces experienced during spaceflight. The material is composed of fire retardant properties, which provides added flight safety.

XCOR’s Lynx spacecraft is continuing to take form and looking more flight ready each day, but the engineers are in no rush. Designing and constructing a spacecraft as complicated and game-changing as the XCOR Lynx is no simple task. As the spacecraft nears completion, XCOR is accepting customers for exploration flights, science and payloads, and leasing opportunities.

Be sure to “Like” AmericaSpace on Facebook and follow us on Twitter: @AmericaSpace

.

Unfortunately XCOR just raised the price of a flight 50%, to $150,000. I visited the company’s facilities in 2009 and was impressed with everyone I met. I’m not criticizing the increase, which I assume was necessary. But for many, like me, who might have been able to come up with $100,000 one way or another, the trek is now out of reach.

There’s always Blue Origin’s New Shepherd system.

Well, you could pay $50K more to only go to 80km altitude with Virgin Galactic.

Give time it will come down dramatically….

Please, the vehicle is nowhere near completion.

It’s a great business plan; cashing in on all those 9 year olds trapped in 50 year old bodies who just have to have astronaut wings. A perfect example of NewSpace entrepreneurship.

Thanks for the nice report Talia. I couldn’t be more proud of my friends at Xcor.

Despite the price increase, we in the research community are extremely excited about that other aspect of the business, the Lynx as a reusable sounding rocket! For the cost of one Terrier or Black Brant, dozens of Lynx flights can be purchased. As a bonus, you can ride along with your instrument payload then look forward to a nice runway touchdown instead of the usual trek across some barren desert or tundra to retrieve (too often only what’s left) of your payload.