Last June, leading rocket propulsion manufacturer Aerojet Rocketdyne successfully completed a series of hot-fire tests with a liquid oxygen/kerosene Baby Bantam demonstration engine—an engine that was entirely constructed with 3-D printing. It was the first rocket engine to be entirely constructed with 3-D printing, and this week that work helped secure Aerojet the award of a defense contract by Wright-Patterson Air Force Base (through the Defense Production Act Title III Office) for large-scale additive manufacturing development (also known as 3-D printing) and demonstration.

Working closely with their subcontractors, Aerojet will design and develop larger scale parts to be converted from conventional manufacturing to 3-D printing, using multiple large selective laser melting machines to develop liquid rocket engine applications for national security space launch services.

“Our liquid rocket engines have been used for half a century and our products are highly efficient and complex with a safety and reliability record that is unparalleled,” said Jeff Haynes, program manager of Additive Manufacturing at Aerojet Rocketdyne. “Incremental manufacturing advances have been applied over the history of these programs with great success. Additive manufacturing shifts these advances into high gear and ultimately transforms how these engines are produced.”

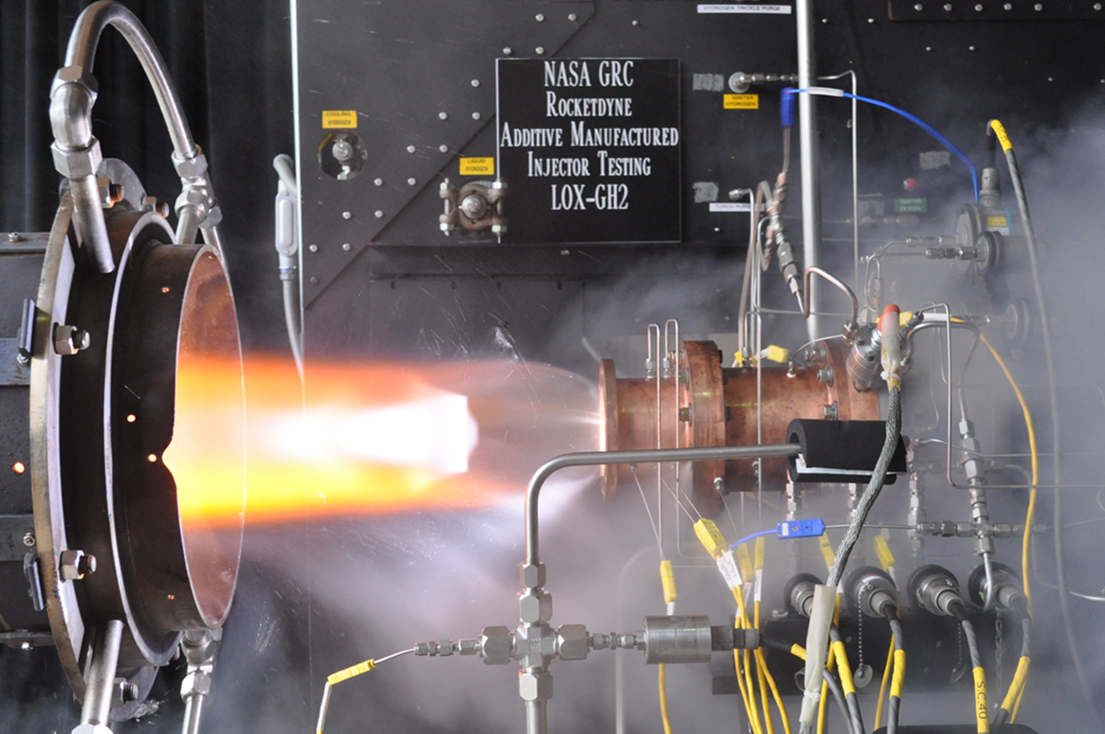

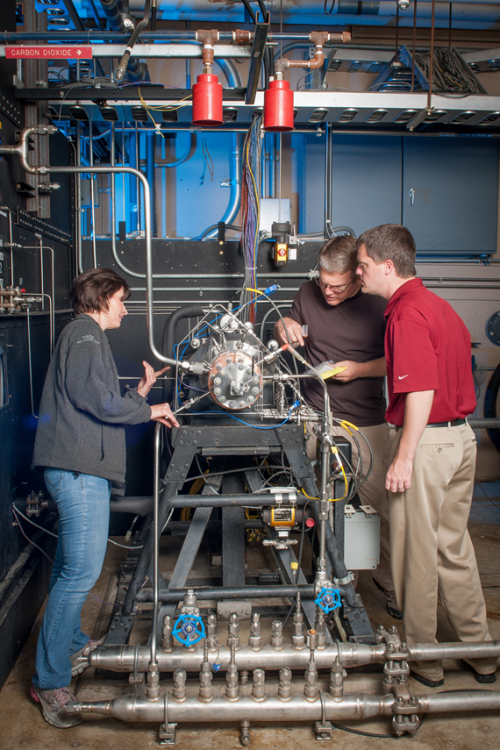

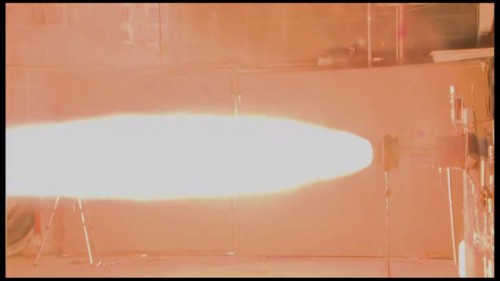

Aerojet Rocketdyne is no stranger to additive manufacturing. The company has had an extensive partnership with NASA under an unfunded Space Act Agreement, which led to a previous series of successful hot-fire tests in 2013 of a 3D-printed liquid rocket engine injector system at the agency’s Glenn Research Center in Cleveland, Ohio (lead image). Being part of Aerojet Rocketdyne’s multi-year additive manufacturing development efforts, these earlier tests opened the way for the development of their new entirely 3D-printed engine, affectionately called “Baby Bantam” for being at the low-end of the company’s Bantam family of liquid rocket engines, capable of producing a thrust of 5,000 pounds.

The 3-D printing method that was used for its construction, called Selective Laser Melting, or SLM, constructs 3-dimensional metal parts by utilizing a high-power laser beam to fuse together successive layers of fine metallic powder and melt them into a homogenous part. This process led to the 3D-printed Baby Bantam engine having some impressive advantages over its conventional counterparts: Its production cycle was reduced from approximately a year to a couple of months, while the engine’s moving parts were reduced from a dozen to just three, including the entire injector and dome assembly, the combustion chamber and a throat, and the nozzle section. This streamlined approach helped to reduce production costs dramatically as well, which, according to Aerojet Rocketdyne, were more than 65 percent lower than that of more conventional manufacturing processes.

“Additive manufacturing is an example of one tool that we (Aerojet Rocketdyne) are using to both enable new designs and improve product cost, as well as reduce lead times for both new and legacy products,” said Dr. Jay Littles, director of Aerojet Rocketdyne’s Advanced Launch Propulsion Programs, in an interview with AmericaSpace on the company’s use of 3-D printing last June. “The Baby Bantam engine demonstration effort provides a good example; our lean design tools, combined with the use of Additive Manufacturing, reduced this overall effort to approximately 20 percent of a traditionally approached similarly sized engine demonstration effort in terms of schedule, and at approximately 30 percent of the cost. The specific benefits will vary by application, but these tools really are changing the way we can perform rapid technology development and feasibility assessments of new designs and configurations.”

Under the new defense contract, Aerojet Rocketdyne will demonstrate three different alloys with these larger additive manufacturing machines to include nickel, copper, and aluminum alloys. Parts ranging from simple, large ducts to complex heat exchangers are planned to be demonstrated in full scale, and the program scope is expected to replace the need for castings, forgings, plating, machining, brazing, and welding.

“We have developed and successfully demonstrated additive-manufactured hardware over the last four years but the machines have been limited in size to 10-inch cubes,” said Steve Bouley, vice president of Space Launch Systems at Aerojet Rocketdyne. “These next generation systems are about six times larger, enabling more options for our rocket engine components. We are extremely honored to have received this contract, and foresee the day when additive-manufactured engines are used to boost and place important payloads into orbit. The end result will be a more efficient, cost-effective engine.”

NASA has been on the leading edge of the development and integration efforts of additive manufacturing processes into the U.S. manufacturing industry, with the results of these efforts being freely available to private space companies. These include a series of successful hot-fire tests last year of a subscale model of the agency’s iconic RS-25 rocket engine that had some of its parts made with 3-D printing technologies at the Marshall Space Flight Center in Huntsville, Ala. Outside of NASA, the California-based Space Exploration Technologies, or SpaceX, has been one of the high-profile private space companies to also acknowledge the value of 3-D printing by employing it in the construction of the SuperDraco—the engine that will power the company’s next generation Dragon V2 spacecraft, whose combustion chamber was manufactured with 3D-printed materials.

Article written by both AmericaSpace writers Mike Killian and Leonidas Papadopoulos.

Want to keep up-to-date with all things space? Be sure to “Like” AmericaSpace on Facebook and follow us on Twitter: @AmericaSpace

Hi Mike,

Great article.

Look forward to future articles as this program progresses.

I want to see work on M-1 restarted myself