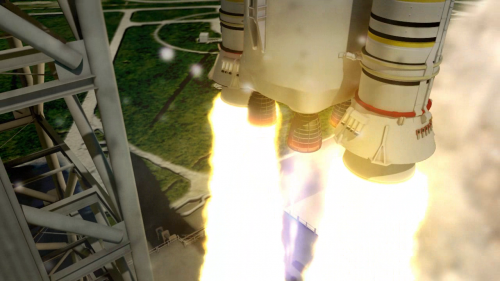

Fifty years ago, tomorrow, on 23 April 1966, a reverberating roll of thunder, accompanied by an orange-red glimmer of flame, brought a patch of Hancock County, Miss., on the banks of the scenic East Pearl River, to a figurative and literal standstill. In the gray mist and murk of a late spring morning, the S-II-T—the Structural and Dynamic Test Vehicle for the second stage of the mighty Saturn V rocket, which would one day deliver the first humans to lunar orbit and to the Moon’s surface—underwent its inaugural “hot-fire” test. For 15 seconds, the stage’s five J-2 engines pummeled the A-2 Test Stand with around a million pounds (450,000 kg) of propulsive yield. It was the opening trial of the largest and most powerful liquid oxygen/hydrogen rocket stage ever built, as well as representing an integral component of the largest and most powerful booster ever brought to operational status. “I don’t know yet what method we will use to get to the Moon,” Wernher von Braun once remarked, “but I do know that we have to go through Mississippi to get there.”

And 50 years on, what was then known as the Mississippi Test Facility (MTF)—but which has, since May 1988, been named in honor of U.S. Senator John C. Stennis, a Democrat who represented Mississippi for more than four decades—continues to push the boundaries of innovation in propulsion technology. The site is currently being actively used by over 30 local, state, national, international, private and public companies, including Orbital ATK, SpaceX, and Blue Origin. However, perhaps Stennis’ most visible occupant is NASA itself, currently developing its mammoth Space Launch System (SLS) booster and gearing toward the long-awaited maiden voyage, Exploration Mission (EM)-1, in November 2018.

The genesis of the site came in the immediate aftermath of President John F. Kennedy’s 25 May 1961 commitment to land an American astronaut on the Moon, before the end of the decade. Its location was dictated by the need for it to reside midway between the Saturn V rocket’s manufacturing site at the Michoud Assembly Facility (MAF) in New Orleans, La., and NASA’s launch complex at Cape Canaveral in Florida. Moreover, the rocket-testing site needed to be accessible by barge, since the engines needed for the massive booster were too large to be transported overland. The Mississippi Test Facility was formally announced by NASA in October 1961 and occupied a 13,500-acre (55 km2) site in South Mississippi, surrounded by a 125,000-acre (506 km2) acoustical buffer zone. It lay about 35 miles (56 km) from MAF and was administered by NASA’s Marshall Space Flight Center (MSFC) in Huntsville, Ala. Later known as “NASA Mississippi Test Operations,” it was ultimately renamed the Mississippi Test Facility (MTF) in July 1965.

The Rocket Propulsion Test Complex was critically tasked with preparing the Saturn V propulsion systems for flight. Of this complex, the A-1 and A-2 test stands—built between 1963 and 1966—were designed to certify the 81.5-foot-long (24.8-meter) S-II, whose five J-2 engines would burn for six minutes to deliver the Apollo Command and Service Module (CSM) and, ensconced within the S-IVB third stage, the Lunar Module (LM), into an Earth parking orbit. Standing 200 feet (60 meters) in height, the A-1 and A-2 test stands could handle thrust loads in excess of a million pounds (450,000 kg) and temperatures of up to 3,300 degrees Celsius (6,000 Fahrenheit).

The first firing, on 23 April 1966, was conducted on the A-2 test stand and was closely monitoed by a team of NASA engineers at the nearby Test Control Center. Countdown operations had begun 25 hours earlier, in the small hours of the 22nd, and high-level visitors and television cameras had been on hand to witness and record the historic event. “Issue after issue, not entirely unexpected, arose through that first day and into the night,” NASA explained in a recent commemorative news release. “Some visitors left; others grabbed snatches of sleep wherever they could. Teams of technicians worked through the hours to address problem areas.” At length, the ignition of the five J-2 engines flared through the mist and, within 15 seconds, as planned, they fell silent. The first test was complete. “And it’s hard to overestimate the impact of the event,” NASA noted. “The Space Age had arrived in South Mississippi and the United States was headlong on its way to the Moon.”

The Deep South would indeed help to forge America’s path into deep space. Less than a month later, the S-II-T completed its first full-duration firing, lasting 354.5 seconds, but a few days thereafter it ruptured when its liquid hydrogen tank failed under pressure. Several North American Aviation technicians, monitoring the test, received minor injuries and a subsequent Board of Inquiry found that the tank had been pressurized beyond its design limits and called for tighter controls over future test procedures. Over the course of the next ten months—despite a handful of technical difficulties—and S-II test hardware was successfully put through its paces and a key component in the United States’ effort to reach the Moon was triumphantly validated. The last rocket stage test at the site in support of the Apollo Program was conducted in October 1970.

In March of the following year, with the first Apollo lunar landings successfully accomplished, the MTF was retasked to support the development of the RS-25 Space Shuttle Main Engine (SSME). Three of these throttleable liquid oxygen/hydrogen powerplants would be installed into the aft compartments of each shuttle and would serve to power five orbiters towards orbit on 135 occasions between April 1981 and July 2011. Both the A-1 and A-2 stands required extensive modification to handle the smaller SSME and the various engines were extensively tested between 24 May 1975 and 29 July 2009. The first test did not include an actual ignition of the SSME, but on 12 June 1975 the engine was successfully ignited and a couple of weeks later, on the 24th, it achieved a full-flight-duration firing. In April 1978, three SSMEs were test-fired simultaneously.

Four years after the first shuttle mission, A-1 and A-2—together with the nearby B-1 and B-2 stands, utilized in the late 1960s for testing the Saturn V’s S-IC core stage—were added to the U.S. National Register of Historic Places (NRHP) and designated as a U.S. National Historic Landmark (NHL). These dedications, incidentally, occurred on 3 October 1985, the very day that NASA’s fourth shuttle, Atlantis, rocketed into orbit on her maiden voyage. The site completed its 1,000th SSME test-firing in February 1988 and its 2,000th in July 1992. More than a decade later, in January 2004, the site hosted a significant milestone, as the SSME passed a cumulative million seconds (around 280 hours) of operations, including more than 3,000 test-firings.

It also changed its name on two occasions. In June 1974, it was named National Space Technology Laboratories (NSTL)—reporting directly to NASA Headquarters in Washington, D.C.—and finally, in May 1988, President Ronald Reagan named it for Sen. Stennis. In giving the rocket-testing facility its current name, NASA paid homage to the senator’s “steadfast leadership and staunch support of the nation’s space program”. By strange coincidence, Sen. Stennis died on 23 April 1995, exactly 29 years to the day since the A-2 test stand first reverberated to the roar of J-2 engines.

Designated a Center of Excellence for large propulsion system testing by NASA Administrator Dick Truly in December 1991, Stennis went on to host the High Heat Flux Facility—charged with materials testing for future hypersonic space vehicles—and in mid-1994 assumed program management for all SSME test operations. Each incarnation of the shuttle’s main engines in the post-Challenger era, including the Block I and Block II SSMEs designed to support International Space Station (ISS) construction, was exhaustively tested at Stennis, as were cryogenic tanks for the proposed X-33 Reusable Launch Vehicle (RLV).

In September 2006, the A-1 stand was used for its first SSME firing, before being handed over in November for testing of the next-generation J-2X engines—derived from their earlier S-II and Saturn V heritage—which were then under consideration for NASA’s Beyond Low-Earth Orbit (BLEO) aspirations. At least one (and possibly two) J-2Xs were expected to be used aboard the Earth Departure Stage (EDS) of the later-canceled Ares V heavylift rocket. Shortly thereafter, the construction of a new “A3” stand, measuring 300 feet (90 meters) tall, got underway, tasked with testing rocket engines at simulated altitudes of up to 100,000 feet (30,000 meters). Elsewhere, testing of J-2X gas generator hardware got underway in the fall of 2007.

Following President Barack Obama’s termination of the Constellation Program—which included Ares V—and the birth of SLS in the fall of 2011, efforts to implement the J-2X into the new booster continued with renewed vigor. A 500-second test of engine components was conducted at Stennis in November 2011, followed by an 1,150-second test of the J-2X powerpack in June 2012. By the close of that summer, Stennis had supported further tests, which passed 1,350 seconds, and the J-2X engine passed through gimbal tests in 2013.

In parallel developments, other SLS hardware was also put through its paces at Stennis. In January 2015, following the decision to implement four shuttle-heritage RS-25s into each core stage of the new booster, Engine No. 0525 was test-fired on the A1 stand for 500 seconds. This inaugural series concluded the following August, but the pace showed no sign of slowing down. Last November, Engine No. 2059—an SSME with actual flight experience, which powered shuttle Endeavour’s final mission on 16 May 2011—was installed into the A1 stand. Since NASA’s current inventory of 16 shuttle-heritage RS-25s will be lost after the first few SLS missions, the space agency has also contracted with Aerojet Rocketdyne to restart production of the old engine for its BLEO future. It is therefore certain that Stennis will continue to reverberate to the sound of the old SSME for the foreseeable future.

Nor is NASA the only occupant of Stennis. In February 2010, Stennis partnered with Orbital Sciences Corp. to test the AJ-26 engines for the Antares booster. Later that year, an AJ-26 was delivered and installed into the A-1 stand and successfully test-fired in November. This kicked off an ambitious test series which enabled Antares to conduct its first flight in April 2013 and begin a complex series of cargo resupply missions to the International Space Station (ISS)—via its Cygnus cargo ship—from September 2013 onwards. Although halted by the October 2014 failure of the ORB-3 Antares, the booster has undergone significant upgrades and its powerplant suite has been replaced by the Russian-built RD-181 engine, with a first flight tentatively scheduled for June 2016.

NASA and SpaceX also cut the ribbon at Stennis’ E-2 stand in April 2014, to mark the start of testing of the methane-fueled Raptor engine, whilst the E-3 stand was first employed in 2012 for tests of the liquid oxygen/methane engine of Project Morpheus, which may support future cargo missions to the surfaces of the Moon, Mars or asteroids. Elsewhere, in October 2012, Blue Origin tested the thrust chamber assembly for its BE-3 engine in the neighboring E-1 test cell.

Ten years ago, just two days shy of the 40th anniversary of the first S-II-T test, an SSME was fired on the A-2 stand. And today, as America stands on the threshold of departing Earth’s gravitational “well” for the first time in five decades, Stennis’ legacy continues. Only weeks ago, in March 2016, Engine No. 2059 was successfully test-fired for 500 seconds. This is expected to be followed by a new raft of tests in the summer of 2016 with the Engine Nos. 2062 and 2063—the two as-yet-unflown RS-25s, in addition to Aerojet Rocketdyne’s inventory of 14 flown shuttle-era SSMEs—ahead of an all-out firing of the SLS core stage in the fall of 2017. This latter event will see the core equipped with the four-strong complement of RS-25s, as it will be for its maiden voyage in November 2018.

In the meantime, the structural steelwork for Stennis’ B-2 test stand was strengthened and raised in height during 2013-2014, as NASA prepares it to support the SLS core stage. Following activation for SLS operations this year, B-2 will undergo modal tests to assess its structural vibration modes, tanking tests to verify pre-launch sequences for pressurizing SLS stage systems and for filling and draining propellants and the eventual “hot-firing” of all four RS-25 engines of the core stage. The tanking tests will mark the first occasion that cryogenics will have been introduced into an SLS core stage. “NASA plans only one or two full tests,” it was noted in 2014, “since the stage is designed for a limited number of chilldowns, including those related to pre-launch and launch activities.”

Interestingly, the B-2 and neighboring B-1 stands at Stennis were originally developed in the 1960s to support testing of the Saturn V’s mighty F-1 engine. In October 1998, Stennis and the Delta IV booster’s manufacturer, Boeing, entered into agreement to use B-1 for testing and integration of the RS-68 liquid oxygen/hydrogen engine. As part of the deal, Boeing invested $8 million to upgrade B-1, as well as an equivalent sum into B-2 for additional testing of the Common Booster Core (CBC) for the Delta IV. When it became operational, the RS-68 marked the first large liquid-fueled engine to be developed in the United States in a generation—since the SSME, in fact—and it completed its first flight aboard the maiden voyage of the Delta IV in November 2002. Since then, the Delta IV has proven a reliable heavylifter of the United Launch Alliance (ULA) fleet of boosters and has completed no fewer than 31 missions, most recently in February 2016.

In honoring tomorrow’s anniversary of 50 years since rocket engines roared across this scenic area of the East Pearl River, the agency offered a word of reminder of the significance of that early testing and of the employees who made it possible. Many engineers and operators who enabled and witnessed the first test still live in the area and some workers at Stennis are second- or even third-generation family members. “There is a real sense of history at this place,” said current Stennis director, Dr. Rick Gilbrech. However, he acknowledged that, as well as honoring the past, Stennis was laying the foundations for the future.

“The record of excellence is continuing as we test engines for NASA’s new Space Launch System Program, which will carry humans deeper into space than ever before, and eventually to Mars,” said Dr. Gilbrech. “What started here in 1966 has grown tremendously. When you talk American space exploration, the road to deep space continues to run through Stennis.”

Want to keep up-to-date with all things space? Be sure to “Like” AmericaSpace on Facebook and follow us on Twitter: @AmericaSpace

I lived in Hancock County, Mississippi (Bay St. Louis) for several years. The story told around those parts is that the original test specification was to fire all five J-2 engines at once, but the first time it was tried, the thunderous roar it created caused windows to break for miles around. The story goes on to say that future tests were only for one engine at a time, and that the 20 mile “exclusion zone” around Stennis was established, both as a direct result of the damage to buildings and vehicles from the first test of five engines. Any truth to this? I can’t say that a tour guide ever told that story, but I have certainly heard it repeated at Stennis from time to time.

Not sure what’s up with the letter “I” in my post. They were all there when I wrote it….

Weird thing, writing in this little thing without finding anything showing this is going fine with freaking alphabetic mistakes with “i”.

AttentIon AmerIcaspace! You mIght want to look at thIs: https://wordpress.org/support/topic/jetpack-393-shortcode-embeds-cause-missing-letters?replies=5

“When it became operational, the RS-68 marked the first large liquid-fueled engine to be developed in the United States in a generation—since the SSME, in fact—and it completed its first flight aboard the maiden voyage of the Delta IV in November 2002.”

Hmmm, there was also the BA-810 tested at McGregor, Texas.

“Beal Aerospace on Saturday fired the largest liquid rocket engine built since the historic Apollo program of the 1960s. The 810,000-pound vacuum thrust hydrogen peroxide/kerosene engine, designated the BA-810, is the Stage 2 engine for Beal’s forthcoming BA-2 heavy-lift launch vehicle, scheduled for inaugural launch in 2002.”

And, “It is the largest engine ever built by a private program with no ties or funding by the government.”

From: ‘Beal Aerospace test fires engine for BA-2 rocket BEAL AEROSPACE NEWS RELEASE’ Posted: March 6, 2000 At: SPACEFLIGHT NOW

Maybe that large H2O2/Kerosene ROCKET ENGINE could be very useful for low cost access to LEO.

Where’s that used BA-810 ROCKET ENGINE today?

2 of the Beal engine bells are on display at the Frontiers of Flight museum in Dallas, TX.

Jester Gambolt –

Thanks for the information!

Someday I hope to visit “the Frontiers of Flight museum in Dallas, TX.”

I Ԁo aǥree with all of tɦe idᥱas you have offerеd ⲟn yoսr post.

They’re really convincing and will certainly ԝork.

Still, the posts arre veгy brief for beginners.May you please

lengthen them a bit from subsequent time? Thanks

for the post.