The most efficient rocket engine in history came to life for the seventh time this year yesterday in southern Mississippi, unleashing over a half-million pounds of thrust and sending a thunderous roar across NASA’s Stennis Space Center during a 535-second full duration hot fire test. The same engine that powered NASA’s now retired space shuttle fleet so reliably for three decades, Aerojet Rocketdyne’s RS-25, will again be employed for NASA’s enormous Space Launch System (SLS) rocket, upgraded to meet the new requirements for what will become the most powerful rocket in history, and yesterday’s seventh test fire closed out the first series of test fires under highly instrumented and controlled conditions.

“The completion of this test series is an important step in getting SLS ready for the journey to Mars,” said Steve Wofford, engines manager at NASA’s Marshall Space Flight Center in Huntsville, Alabama, where the SLS Program is managed for the agency. “The RS-25 engine gives SLS a proven, high performance, affordable main propulsion system. It is one of the most experienced large rocket engines in the world, with more than a million seconds of ground test and flight operations time.”

The 535-second test fire, carried out by development engine #0525 on the historic A-1 test stand, went off without issue—something that has come to be expected of the RS-25 engines. The RS-25 was the first reusable rocket engine in history, as well as being one of the most tested large rocket engines ever made, having conducted more than 3,000 starts and over one million seconds (nearly 280 hours) of total ground test and flight firing time over the course of NASA’s 135 space shuttle flights.

“It is great to see this revered engine back in action and progressing full steam ahead for launch aboard Exploration Mission-1 in 2018,” said Julie Van Kleeck, vice president of Aerojet Rocketdyne’s Advanced Space & Launch Programs business unit. “The RS-25 is the world’s most reliable and thoroughly tested large liquid-fueled rocket engine ever built.”

The engines proved their worth time and time again, but the RS-25 now requires several modifications to adapt to the new environment they will encounter with SLS and meet the giant 320-foot tall rocket’s enormous thrust requirements.

Yesterday’s test fire will provide engineers with critical data on the engine’s new state-of-the-art controller unit—the “brain” of the engine, which allows communication between the vehicle and the engine itself, relaying commands to the engine and transmitting data back to the vehicle. The new controller also provides closed-loop management of the engine by regulating the thrust and fuel mixture ratio while monitoring the engine’s health and status, thanks to updated hardware and software configured to operate with the new SLS avionics architecture.

“We’ve made modifications to the RS-25 to meet SLS specifications and will analyze and test a variety of conditions during the hot fire series,” said Wofford. “The engines for SLS will encounter colder liquid oxygen temperatures than shuttle; greater inlet pressure due to the taller core stage liquid oxygen tank and higher vehicle acceleration; and more nozzle heating due to the four-engine configuration and their position in-plane with the SLS booster exhaust nozzles.”

For shuttle flights the engines pushed 491,000 pounds of thrust during launch—each—and shuttle required three to fly, but for SLS the power level was increased to 512,000 pounds of thrust per engine (more than 12 million horsepower). The SLS will require four to help launch the massive rocket and its payloads with a 70-metric-ton (77-ton) lift capacity that the initial SLS configuration promises.

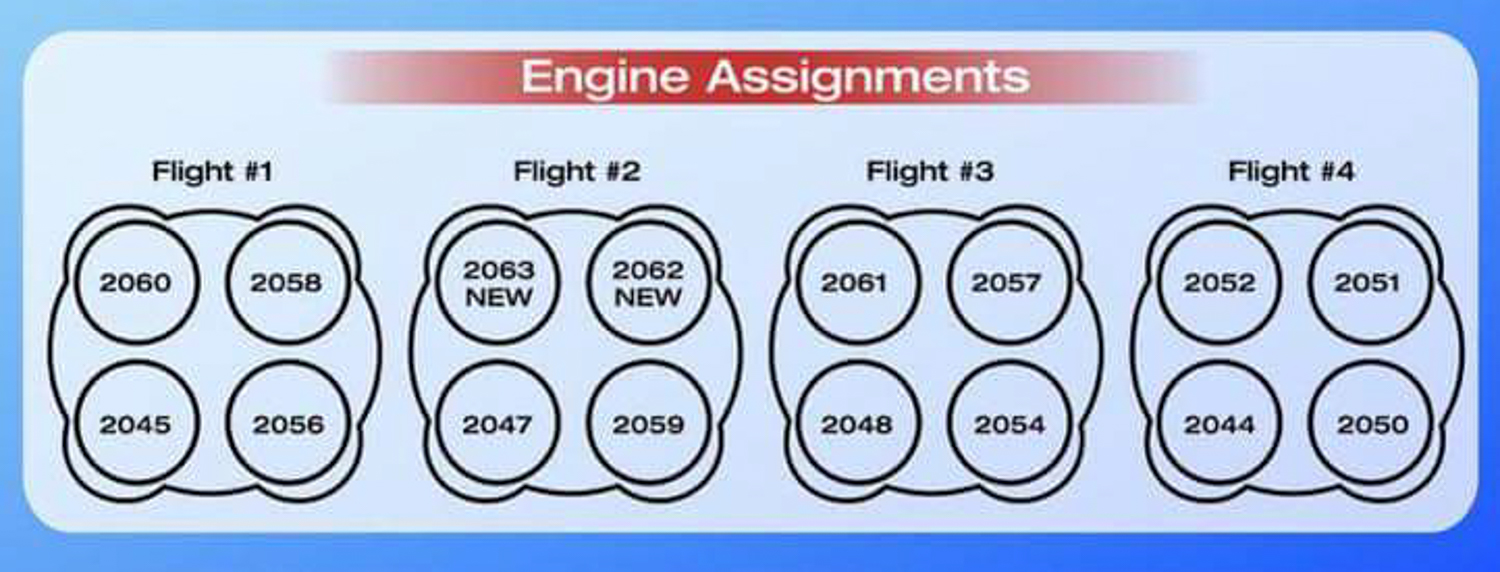

Aerojet Rocketdyne and NASA currently have 16 RS-25 engines in inventory at Stennis—14 of which are veterans of numerous space shuttle missions. Aerojet Rocketdyne just recently finished assembly of the 16th engine (engine 2063), one of the space agency’s two “rookie” RS-25s. It will be one of four RS-25 engines that will be employed to power the SLS Exploration Mission-2 (EM-2), the second SLS launch currently targeted for the year 2021. All of the engines have already been assigned to their SLS flights.

“The engine that was tested yesterday continues demonstration of the new controller’s functionality and the engine’s ability to perform to SLS requirements,” added Jim Paulsen, vice president, Program Execution, Advanced Space & Launch Programs at Aerojet Rocketdyne. “The new controller provides modern electronics, architecture and software. It will improve reliability and safety for the SLS crew as well as the ability to readily procure electronics for decades to come. We are conducting engine testing to ensure all 16 flight engines in our inventory meet flightworthiness requirements for SLS.”

Testing of RS-25 flight engines for the initial SLS missions will begin at Stennis this fall, and another 10 test fires will be conducted with another development engine, which will be put through its paces for a grand total of 4,500 seconds.

Known as the “Ferrari of rocket engines”, the RS-25 can handle temperatures as low as minus 400 degrees (where the propellants enter the engine) and as high as 6,000 degrees as the exhaust exits the combustion chamber where the propellants are burned.

To put the power of the Aerojet Rocketdyne-built RS-25 engines into perspective, consider this:

- The fuel turbine on the RS-25’s high-pressure fuel turbopump is so powerful that if it were spinning an electrical generator instead of a pump, it could power 11 locomotives; 1,315 Toyota Prius cars; 1,231,519 iPads; lighting for 430 Major League baseball stadiums; or 9,844 miles of residential street lights—all the street lights in Chicago, Los Angeles, or New York City.

- Pressure within the RS-25 is equivalent to the pressure a submarine experiences three miles beneath the ocean.

- The four RS-25 engines on the SLS launch vehicle gobble propellant at the rate of 1,500 gallons per second. That’s enough to drain an average family-sized swimming pool in 60 seconds.

- If the RS-25 were generating electricity instead of propelling rockets, it could provide twice the power needed to move all 10 existing Nimitz-class aircraft carriers at 30 knots.

“There is nothing in the world that compares to this engine,” added Paulsen. “It is great that we are able to adapt this advanced engine for what will be the world’s most powerful rocket to usher in a new space age.”

“This was a great test series for Stennis,” said Ronnie Rigney, RS-25 project manager at Stennis. “Our teams built up a lot of history with space shuttle main engines and were able to use that expertise to meet very challenging test specifications for the RS-25. The testing done here will help ensure the engines perform as needed during actual SLS missions.”

WATCH: RS-25 SLS Development Main Engine Test Fire #7 – Aug. 27, 2015

Be sure to “Like” AmericaSpace on Facebook and follow us on Twitter: @AmericaSpace

Congratulations to all the fine folks at Aerojet Rocketdyne and Stennis Space Center on the successful conclusion of this test series. Go RS-25! Go SLS!

I am in complete and total agreement with you Byron, this is GREAT news. Also, thanks to the individuals who prevented the American human space flight program from being ended after the cancellation of Constellation. To the Moon, Mars, and beyond! Go RS-25! Go SLS! Go Orion! Go NASA!