NASA is full steam ahead with the Space Launch System, as years of development and manufacturing continue transitioning into flight hardware final assembly and integration for the upcoming Artemis moon missions after the turn of the decade.

The agency just ordered a third rocket core and is finalizing details with Boeing for a contract of up to 10, while workers at the launch site in Florida practice processing ops with a recently arrived pathfinder, and technicians at Michoud Assembly Facility in New Orleans install the four flight engines on the bottom of the enormous 212-foot tall core stage for the first SLS flight – Artemis 1.

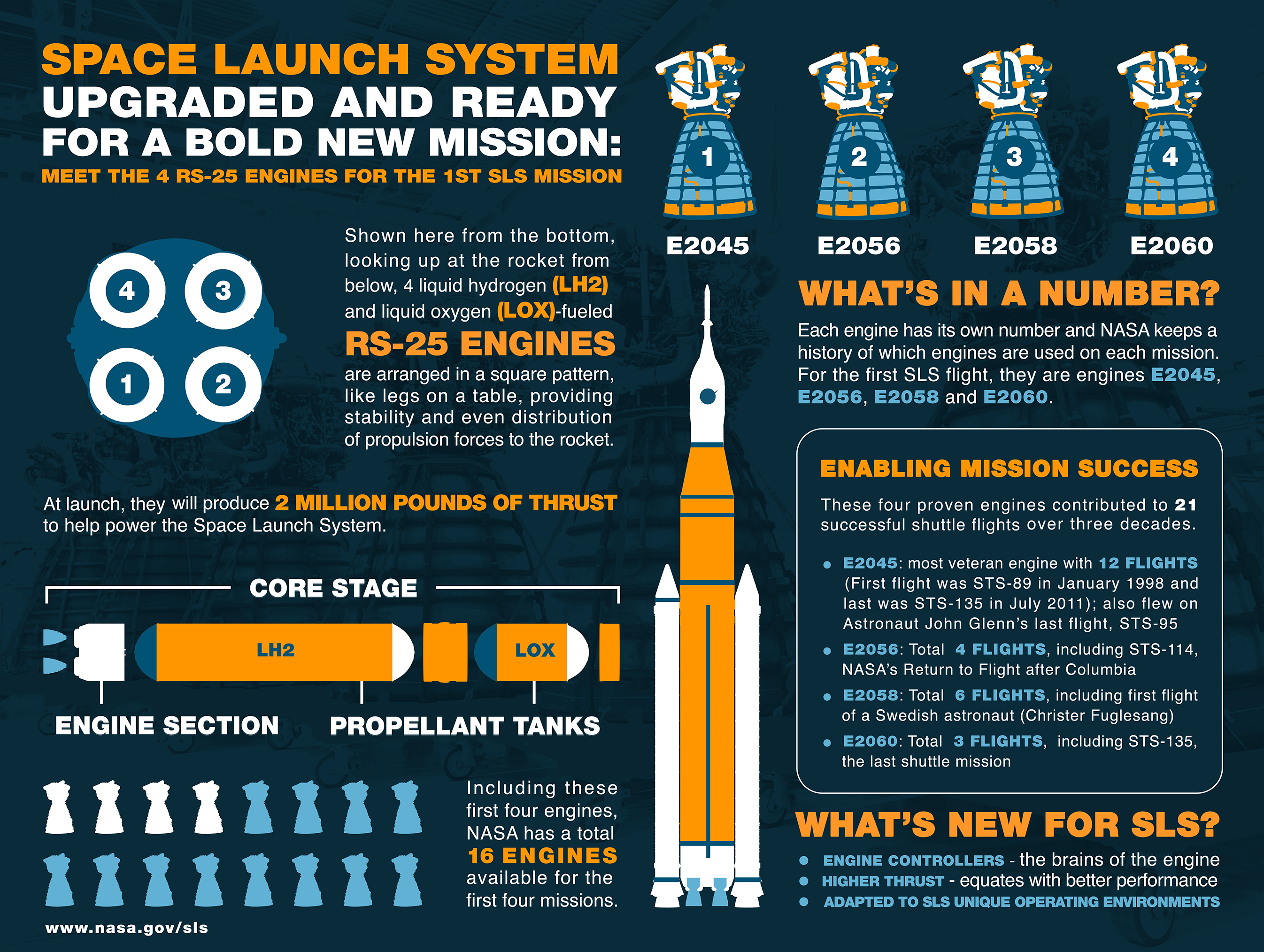

Known as the Ferrari of rocket engines, the Aerojet Rocketdyne RS-25s which once helped power the space shuttles off world have been modified to produce more power, each featuring a new controller, or ‘brain’, to help control engine operation and facilitate communication between the engines and rocket. Guzzling 733,000 gallons of liquid oxygen and liquid hydrogen, the four engines will produce more than 2 million pounds of thrust at launch.

Over the last 4 years, all 16 of the engines have been modified from their reusable shuttle-era configurations, tested, and cleared for flight on the first four SLS Artemis missions.

NASA and Boeing finished assembling and joining the main structural components of the first core stage last month, and with the first engine now mated to the rocket technicians will now integrate the propulsion and electrical systems, then repeat for each of the other three engines, completing final assembly of the Artemis I core stage in December.

At the same time, crews will also be building, outfitting and assembling the core stage for Artemis II, the first mission that will send astronauts to orbit the Moon.

The rocket will then move to Stennis Space Center next year for a series of tests that will build like a crescendo over several months and climax with a full-duration test fire, a ‘Green Test Run’ where the integrated rocket and engines will come to life together for the first time, just like on launch.

The test series will validate the vehicle as ready for flight, demonstrating that the engines, tanks, fuel lines, valves, pressurization system, and software all perform together as planned on launch day. Pathfinder practice ops were conducted on the test stand this past August to ensure workers are ready when the actual flight hardware arrives.

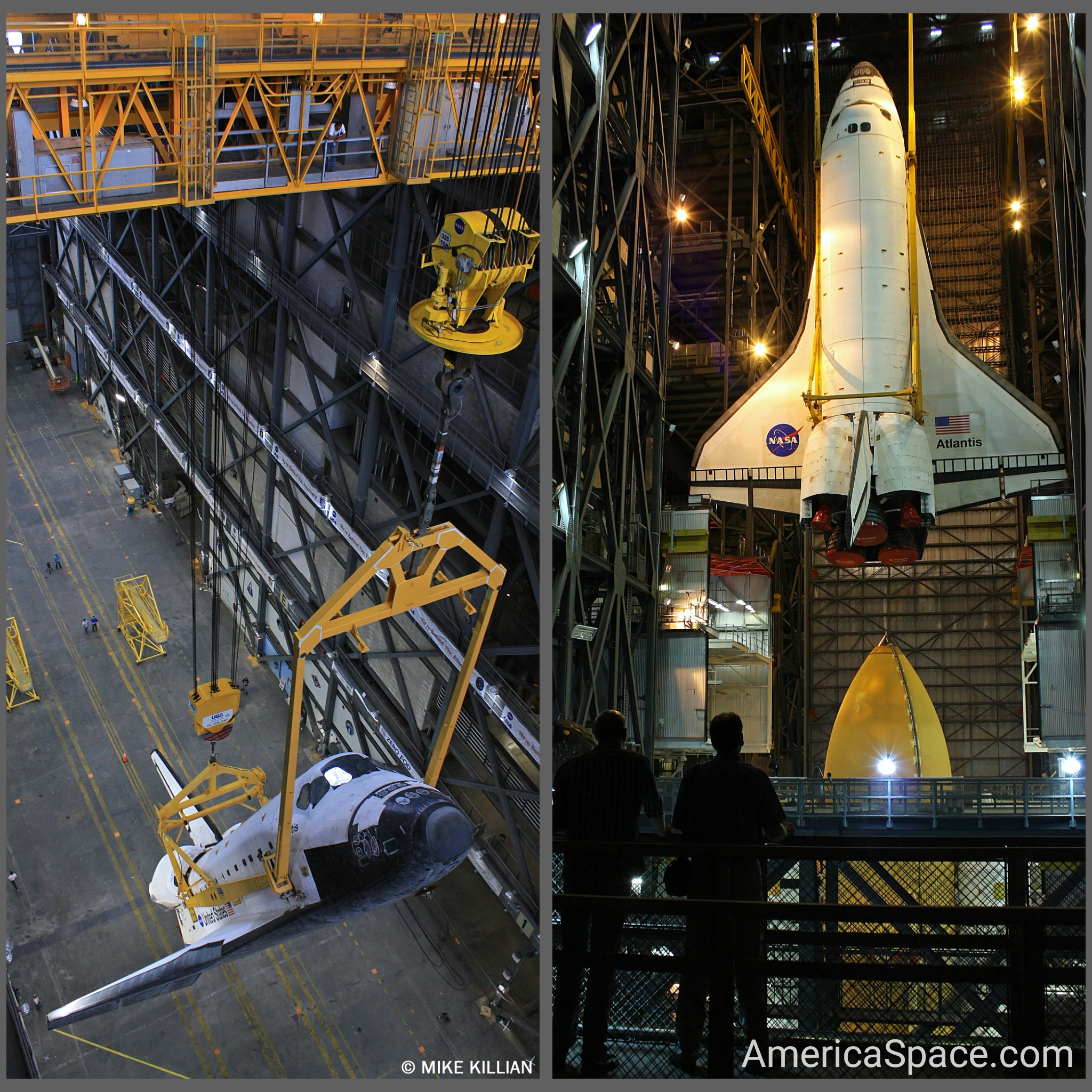

Meanwhile, technicians at the SLS Artemis launch site at Kennedy Space Center have been practicing various launch processing operations with the SLS pathfinder over the last month. Arriving on the refurbished Pegasus barge, teams with NASA’s Exploration Ground Systems and its contractor, Jacobs, have been practicing offloading, moving and lifting maneuvers with the full-scale 225,000 pound mock-up in KSC’s iconic Vehicle Assembly Building (VAB), so that crews are trained on how to handle the giant rocket and certify all ground support equipment works properly before the actual flight booster arrives for Artemis I.

“Experience is the best teacher,” said Jim Bolton, EGS core stage operations manager. “Pathfinders allow crews to practice lifting, accessing and transporting techniques that we prefer not to do for the first time with the flight hardware. Practicing with a pathfinder reduces risk and builds confidence.”

From NASA: “Inside the VAB transfer aisle, a lifting fixture, called a spider, was attached to the top, or forward ring of the core stage pathfinder. A transportation and integration fixture, developed at Marshall, was used to move the spider to the core stage pathfinder to enable installation. With the spider secured in place, another crane was attached to the pathfinder’s aft end lifting brackets. Workers practiced using the cranes to lift the pathfinder horizontally up from its transporter. Then, crane operators performed a procedure called a breakover to slowly move the pathfinder into the vertical position and lift it up and over Level 16 into High Bay 3. A reverse sequence also was performed, with the core stage lifted up from the high bay, lowered down to the transfer aisle, returned to a horizontal position and secured in its transporter.”

“It’s the first opportunity for the entire Kennedy team to verify, validate and execute the engineering and planning associated with handling of the SLS core stage flight hardware, setting the stage for an experienced workforce and efficient processing for the historic Artemis missions,” said Bolton.

Another water deluge sound suppression system test was conducted at Artemis launch pad 39B recently too. During the 30-second test, about 450,000 gallons of water poured onto the Pad B flame deflector, the mobile launcher flame hole and onto the launcher’s blast deck. The system reached a peak flow rate of more than 1 million gallons per minute.

The test was the first time the ground launch sequencer software that will be used on launch day was used to command launch support systems at Pad B from the Launch Control Center. The tests also included a nominal launch countdown flow and a single valve failure test flow to better characterize off-nominal system performance. Post-test analysis are currently underway in preparation for a final water flow test in the coming weeks, involving the hydrogen burn-off igniters.

SUBSCRIBE to our YouTube channel!

While work presses forward across the country towards that highly-anticipated first launch in (hopefully) 2021, NASA just ordered a third SLS core stage from Boeing, the actual rocket NASA hopes will launch the first Artemis crew to land the surface of the moon in 2024, and the agency is finalizing details with Boeing for up to 10 of the rockets, which would take care of Artemis missions through the next decade.

The full contract is expected to be finalized within the next year, and also calls for up to eight Exploration Upper Stages (EUS).

And while there is large bipartisan support in Congress for Artemis, time will tell whether NASA will get the extra funding or support for a 2024 lunar landing, as opposed to 2028. Several politicians question motives behind accelerating a moon landing from 2028 to 2024, as well as where the extra money will come from. NASA’s Administrator, Jim Bridenstine, visited Capitol Hill earlier this month to meet with legislators in an effort to secure an additional $1.6 billion, something the subcommittee of the House Appropriations Committee is not willing to give them without knowing the full program cost estimate. Bridenstine has previously estimated $20-30 billion.

NASA is working with the White House and the National Space Council to find a total price for Artemis and, according to Bridenstine, will release its findings in February 2020 as part of next year’s budget cycle.

.

.

FOLLOW AmericaSpace on Facebook and Twitter!

.

.

Missions » SLS » Artemis »