Standing three stories tall and looking for all the world like a giant tapering cone, a critical piece of the Space Launch System (SLS) destined for the Artemis-1 mission—America’s first voyage to lunar distance with a human-rated spacecraft since Apollo 17 in December 1972—arrived safely on Wednesday, 29 July, at the Kennedy Space Center (KSC) in Florida aboard NASA’s 310-foot-long (95-meter) Pegasus barge.

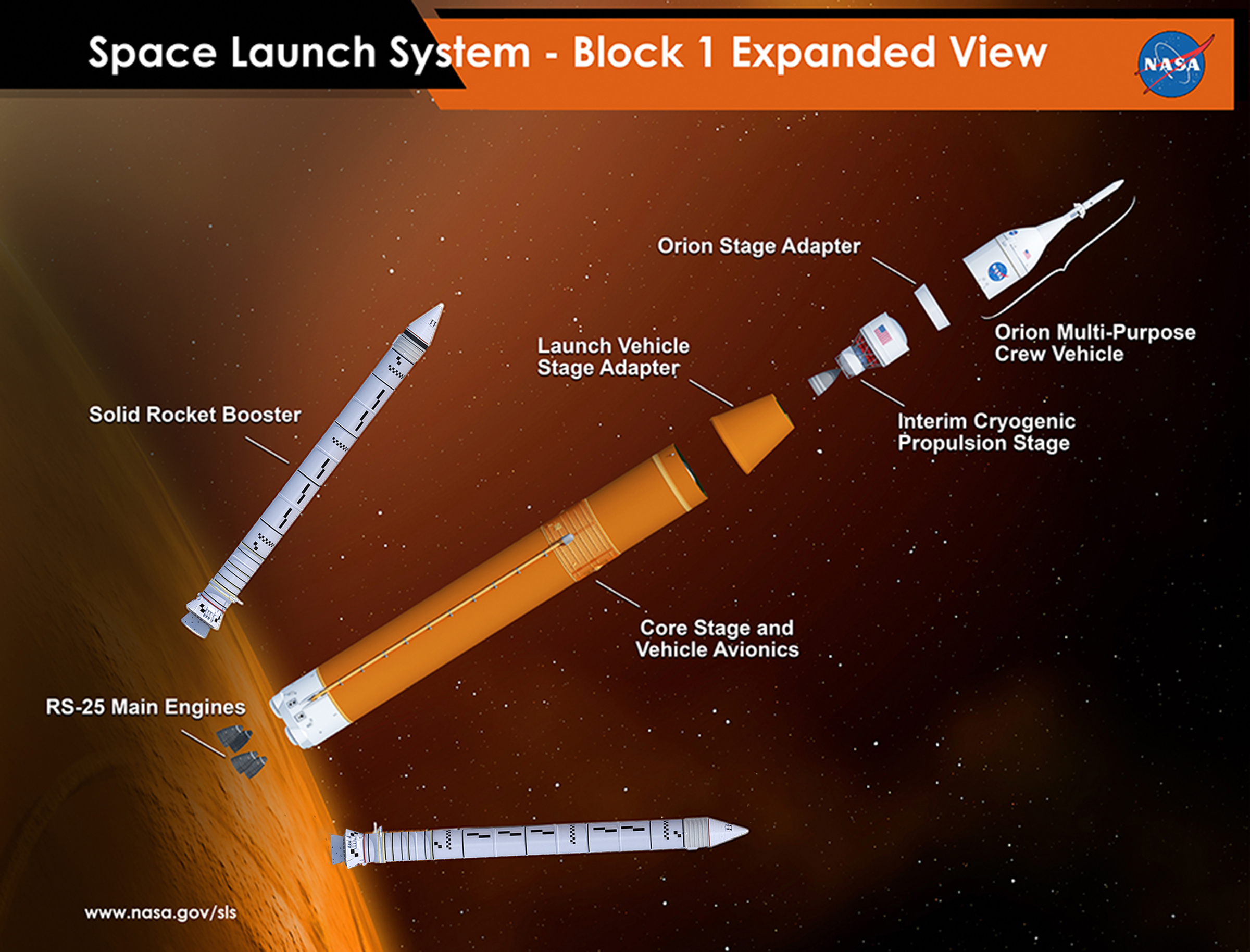

The 10,000-pound (4,500 kg) Launch Vehicle Stage Adapter (LVSA), which links the rocket’s core stage with the Interim Cryogenic Propulsion Stage (ICPS) and protects upper-stage engine hardware, departed NASA’s Marshall Space Flight Center (MSFC) in Huntsville, Ala., on 17 July, and will now be put through processing in High Bay 4 of the Vehicle Assembly Building (VAB), ahead of stacking atop the SLS and its key role in sending Artemis-1 to the Moon late next year.

Almost 30 feet (10 meters) tall and measuring 27.6 feet (8.4 meters) in diameter at the base and tapering to 16.8 feet (5.1 meters) in diameter at the top, the LVSA shipment comes only weeks after NASA wrapped up an extensive structural testing campaign for key elements of the SLS.

“The Launch Vehicle Stage Adapter for NASA’s Space Launch System rocket was the final piece of Artemis-1 rocket hardware built exclusively at NASA’s Marshall Space Flight Center,” said MSFC Director Jody Singer. “This milestone comes as Marshall teams just completed the structural test campaign of the SLS rocket that confirmed the rocket’s structural design is ready for Artemis missions to the Moon.” In honor of the departure, Alabama Gov. Kay Ivey declared 17 July to be “Artemis Day” in Alabama and signed a formal proclamation to that effect. The proclamation described the LVSA as “a key structural element that demonstrates new innovations in the fields of friction-stir welding and vehicle design”.

“The Launch Vehicle Stage Adapter is welded together as two separate cones that are stacked on top of each other,” said Keith Higginbotham, LVSA Hardware Manager at MSFC. “Marshall’s expertise with an innovative process called friction-stir welding and the center’s large robotic weld tools made it possible to build some pieces of the rocket at Marshall, while the core stage was built at the same time by Boeing at Michoud.”

The initial five-year, $60 million contract to design, develop, test, evaluate and certify the LVSA was awarded by NASA to Teledyne Brown Engineering, Inc., of Huntsville, Ala., in early 2014. Under the terms of that contract, the firm partnered with MSFC to use its Advanced Welding Facility to build a Structural Test Article (STA) and two flight units of the adapter, with an option for a third flight unit.

Major welding on panels for the STA got underway in the late summer of 2015, with the innovative friction-stir process joining pieces together by “stirring” their edges without completely melting the metal. The result is a stronger weld than is achievable in standard welding practices. Described by SLS Adapter Manager Brent Gaddes as presenting “challenges, due to its large size and conical shape”, the LVSA was fabricated using a wealth of expertise gained whilst building the stage adapter which linked an Orion spacecraft to the top of a United Launch Alliance (ULA) Delta IV Heavy rocket for the Exploration Flight Test (EFT)-1 mission in December 2014.

Following the completion of its eight vertical welds, the STA was lifted out of the welding machine and in June 2016 was confirmed structurally complete and ready for testing. It was moved to the 65-foot-tall (19.8-meter) test stand at MSFC in October 2016 in readiness for integrated “push, pull and twist” tests with test versions of the SLS core stage and other upper components of the rocket in early 2017. That testing was conducted in tandem with duplicates of the SLS core stage, a frangible joint assembly, the ICPS, the Orion Stage Adapter and Orion spacecraft, as well the LVSA STA, with around 50 test-cases conducted. To make the testing as realistic as possible, more than 500,000 pounds (227,000 kg) of axial hydraulic force and pressures as high as 56 psi (386 kPa) were applied to the test stack, with data gathered from over 1,900 instrumentation channels.

In the meantime, welding on the actual flight hardware for the Artemis-1 LVSA had gotten underway in the late summer of 2016. And it will certainly stand out when the complete SLS stack is fully integrated on the launch pad. During the course of the giant rocket’s Critical Design Review (CDR), it was reported that the LVSA element and the core stage would remain orange, the natural color of their Spray-On Foam Insulation (SOFI), rather than being painted white, as was originally intended.

“Because this section widens so much from top to bottom, it will experience extreme aerodynamic heating during launch,” NASA noted, “and the foam will protect the metal underneath from the high temperatures.” In August 2017, the LVSA was moved from the Advanced Weld Facility to the National Center for Advanced Manufacturing at MSFC for the lengthy SOFI process, applied by robotic and hand-held spray-guns.

“This is an effort of great magnitude physically and programmatically for our company and for Marshall Space Flight Center,” said Jan Hess, president of Teledyne Brown Engineering, Inc., at the time of the SOFI application. “LVSA is the largest piece of a rocket to be manufactured at Marshall in Huntsville since the Apollo era.”

By mid-2018, following the SOFI work, engineers began installing the LVSA’s separation systems and electronics and in March of last year efforts to install the frangible joint assembly—a mechanism designed to break apart, thereby allowing hardware elements to properly separate in flight—got underway.

Having departed MSFC on 17 July aboard the 310-foot-long (94.4-meter) Pegasus barge, the journey time to Florida took 12 days. With the arrival of the LVSA on the Space Coast, another critical component for the Artemis-1 mission is now at its launch site, together with the twin, five-segment Solid Rocket Boosters (SRBs). The core stage, meanwhile, is currently at the midpoint of its eight-step “Green Run” testing campaign at NASA’s Stennis Space Center in Bay St. Louis, Miss., and is expected to undertake a full-flight-duration test-firing of its four RS-25 engines later this fall.

Elsewhere, work on the LVSA hardware for missions beyond Artemis-1 is well underway. Earlier in July, NASA noted that the panels for the LVSA assigned to Artemis-2—a mission currently to send the first human crew to lunar distance since the end of the Apollo era, almost five decades ago—are currently being built. Vertical connecting welds to link the LVSA segments together are underway. Work on the LVSA for Artemis-3, expected to see the first landing of humans on the Moon since the end of the Apollo era, has yet to begin. “Although no work has begun on Artemis-3 hardware, materials for the aluminum plate have been placed on order,” Ray Osorio of MSFC recently told AmericaSpace. “Regarding Artemis-2, we are on track to be hardware ready by around end of May 2022.”

FOLLOW AmericaSpace on Facebook and Twitter!

Missions » SLS » Artemis »