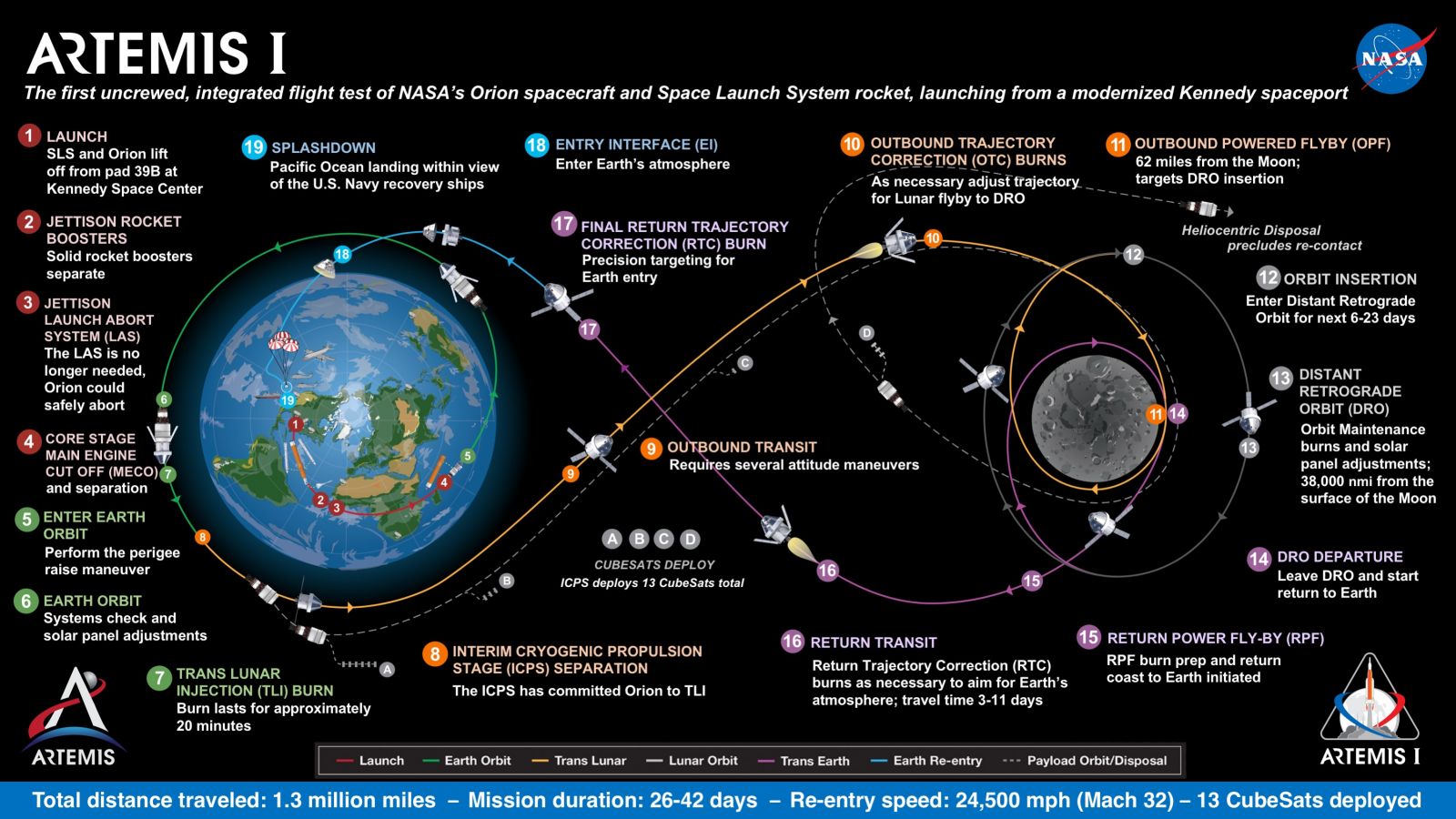

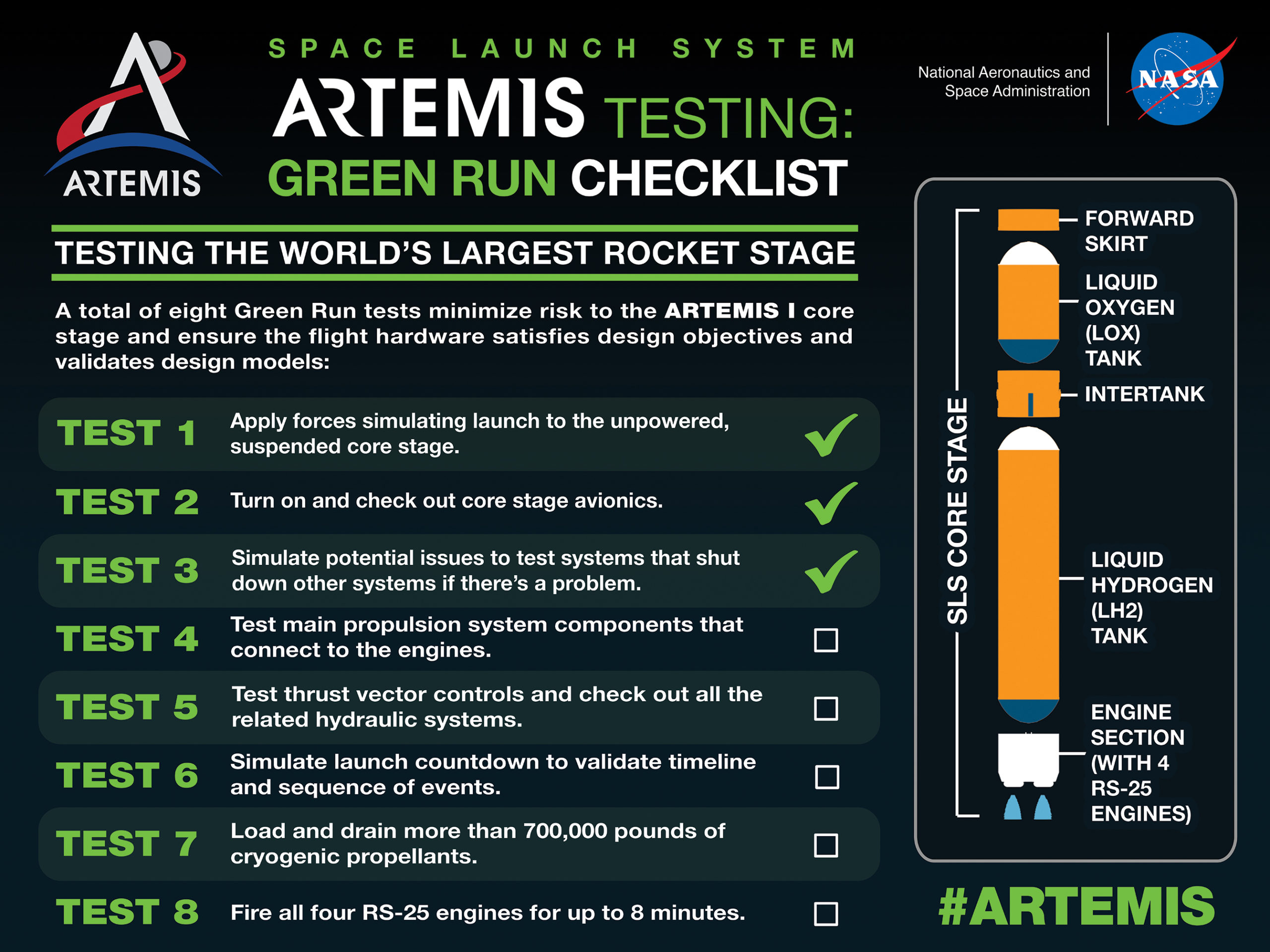

NASA engineers are approaching the midpoint of “Green Run” testing as the Space Launch System (SLS) core stage inches ever closer to a planned full-mission-duration static-firing of its four RS-25 engines, possibly later this fall. The space agency revealed Thursday that the third of eight critical Green Run tests has successfully concluded. The giant rocket, teamed with a pair of five-segment Solid Rocket Boosters (SRBs)—which arrived at the Kennedy Space Center (KSC) in Florida last month from prime contractor Northrop Grumman Corp.’s test site in Promontory, Utah—will send an uncrewed Orion spacecraft around the Moon late in 2021 for the Artemis-1 mission. In doing so, it will demonstrate the first human-rated space vehicle on a voyage to lunar distance since Apollo 17 in December 1972.

Green Run testing on the 212-foot-tall (64.6-meter) SLS core stage is being conducted in the B-2 Test Stand at NASA’s Stennis Space Center in Bay St. Louis, Miss. The core will be powered by four shuttle-era RS-25 engines, generating a combined impulse of about 1.6 million pounds (760,000 kg), which, when combined with the twin SRBs will give the SLS a total thrust at liftoff of 8.8 million pounds (3.4 million kg). This represents an approximately 15-percent increase over the long-since-retired Saturn V, which currently still stands as the largest and most powerful rocket ever brought to operational status.

Testing of the SLS hardware has taken place on numerous fronts across the United States. The five-segment boosters—which derive in design from their shuttle-heritage predecessors—were put through an extensive series of evaluations, culminating in a pair of Qualification Motor (QM-1 and QM-2) firings at Northrop Grumman’s facility in Promontory, Utah, in March 2015 and June 2016, respectively, which tested their performance at “maximum” anticipated operating temperatures of 32 degrees Celsius (90 degrees Fahrenheit) and “minimum” anticipated operating temperatures of 4.5 degrees Celsius (40 degrees Fahrenheit).

More recently, five Structural Test Articles (STAs) of the critical components of the SLS core stage—its upper segment, intertank, liquid hydrogen tank, liquid oxygen tank and engine section—were put through 199 tests at NASA’s Marshall Space Flight Center (MSFC) in Huntsville, Ala. The upper section and intertank were tested first, followed by the engine section which wrapped up in February 2018.

More recently, last December the 149-foot-long (45.4-meter) liquid hydrogen tank, the biggest core stage element, was tested to destruction, and finally the 70-foot-long (21-meter) liquid oxygen tank was put through the wringer. In the case of the tanks, they endured far more punishing pressures and stresses than they can expect to receive on a real mission and provided not only valuable engineering data, but also a close-to-prediction endorsement of computer models.

But the real test of the actual core stage for the SLS which will deliver Artemis-1 to the Moon took the form of the Green Run, conducted in the B-2 Test Stand at Stennis. Built in the 1960s, the stand is part of a dual-position, vertical static-firing complex upon which the S-IC first stage of the Saturn V and its quintet of F-1 engines were tested more than five decades ago and, more recently, housed the Main Propulsion Test Article framework to test the Space Shuttle’s main engines.

As part of preparing for the much larger and taller SLS, the stand saw extensive upgrades to to every major system and the addition of around a million extra pounds (453,500 kg) of steel to extend its framework an additional 100 feet (33 meters) and lengthen its large derrick crane. The new-look B-2 Test Stand was declared operationally “ready” in December 2018.

The Green Run is so named because its “run” of eight fully-integrated test phases will be conducted on new and as-yet-untried (or “green”) flight hardware. Last summer, NASA Administrator Jim Bridenstine stressed the importance of the Green Run in ensuring the safety of astronauts on future SLS flights, increasing the probability of achieving American boots on the Moon by 2024 and identifying technical issues “earlier rather than later”. In August 2019, a full-size structural replica of the SLS core stage, known as the “pathfinder”, was installed into the B-2 Test Stand for a series of fit-checks.

And earlier this year, the real SLS core stage for Artemis-1 made its way from NASA’s Michoud Assembly Facility in New Orleans, La., to Stennis. Delivered aboard the Pegasus barge, it arrived at the B-2 Test Stand dock in the second week of January and was lifted into the stand under optimal wind and weather conditions on the 21st and 22nd. Standing 212 feet (64.6 meters) tall, it is the largest core stage ever built by NASA, dwarfing even the 138-foot-tall (42-meter) S-IC first stage of the Saturn V.

“The SLS core stage is an engineering feat that includes not only the largest rocket propellant tanks ever built but also sophisticated avionics and main propulsion systems,” said Lisa Bates, SLS deputy stages manager. “While the rocket is designed to evolve over time for different mission objectives, the core stage design will remain basically the same. The Green Run acceptance test gives NASA the confidence needed to know the new core stage will perform again and again as it is intended.”

The first of the eight-test Green Run series was completed shortly afterwards, in the form of the “Modal Test”, which utilized mechanical “shakers” to impose dynamic forces on the suspended core stage to identify primary bending modes. Information from this test will aid the verification of vehicle models needed to operate the SLS Guidance, Navigation and Control (GNC) systems.

“Engineers also manually use an impulse hammer to test the spider crane, which holds the stage in place, to help establish a baseline for any impact the test stand or external hardware could have on Green Run testing data,” NASA noted. “Data from the modal test will be used to verify structural vibration modes and flight control parameters for the core stage design.”

The worldwide march of COVID-19 pushed Stennis into a “Level Four” posture on the scale of NASA’s response framework to the coronavirus pandemic in March, with only personnel needed to perform mission-essential activities relating to the safety and security of the center permitted on site.

Work resumed in a reduced capacity in mid-May and at the end of June the second Green Run test—the “Avionics Test”—was successfully completed. As part of this test, the rocket’s avionics, which are distributed throughout the core stage, were powered-up and checked out. This included the flight control computers and electronics and a multitude of sensors which gather flight data and montiro the overall health of the core stage in flight.

The third test, dubbed “Fail-Safes”, checked out the rocket’s safety systems which will shut down operations during testing and incorporated several simulations of potential problems. NASA confirmed the satisfactory completion of the Fail-Safes test in its Thursday update. Next up will be the “Propulsion” test, in which the core will be checked for leaks and command and control operations pertaining to the Main Propulsion System (MPS) elements adjoining the engines will be evaluated. The remaining tests, due to be conducted later this summer and into the fall, are expected to culminate and an up-to-eight-minute-long, full-mission-duration firing of the RS-25 engines.

“This critical test series will demonstrate the rocket’s core stage propulsion system is ready for launch on missions to deep space,” Stennis Director Rick Gilbrech said earlier this year. “The countdown to this nation’s next great era of space exploration is moving ahead.”