NASA and Northrop Grumman Corp. on Friday finalized contracts to develop the Habitation and Logistics Outpost (HALO)—the keystone pressurized element of the lunar-circling Gateway—and deliver it for launch atop SpaceX’s giant Falcon Heavy booster no sooner than November 2024. Under the terms of the $935 million contract, the Dulles, Va.-headquartered Northrop Grumman will assume responsibility for integrating and testing the HALO module with the Maxar-built Power and Propulsion Element (PPE), leading the turnover of the spacecraft with SpaceX and supporting its activation and checkout during the transit from Earth out to lunar orbit in three years’ time.

“NASA is building the infrastructure to expand human exploration further out into the Solar System than ever before, including Gateway, the lunar station that will help us make inspirational scientific discoveries at and around the Moon,” said NASA Administrator and former shuttle veteran Bill Nelson.

“Just as importantly, these investments will help NASA carry out the United States’ horizon goal: to further develop and test the technology and science needed for a human trip to Mars. The HALO is a critical component of Gateway and this exciting announcement today brings us one step closer to landing American boots on both the Moon and Mars.”

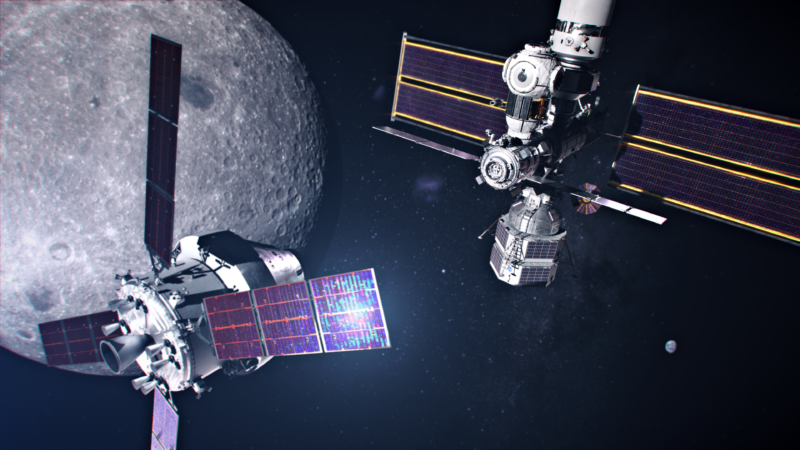

The HALO/PPE spacecraft marks one of the earliest uses of the Near-Rectilinear Halo Orbit (NRHO), a seven-day-long orbital period around the Moon, in which the Gateway will approach the lunar north pole as closely as 1,900 miles (3,000 km) at “perilune” and travel as far as 43,000 miles (70,000 km) over the south pole at “apolune”. Later this year, NASA’s Cislunar Autonomous Positioning System Technology Operations and Navigation Experiment (CAPSTONE) orbiter is slated to conduct the first demonstration of the stability characteristics of this as-yet-untried orbit.

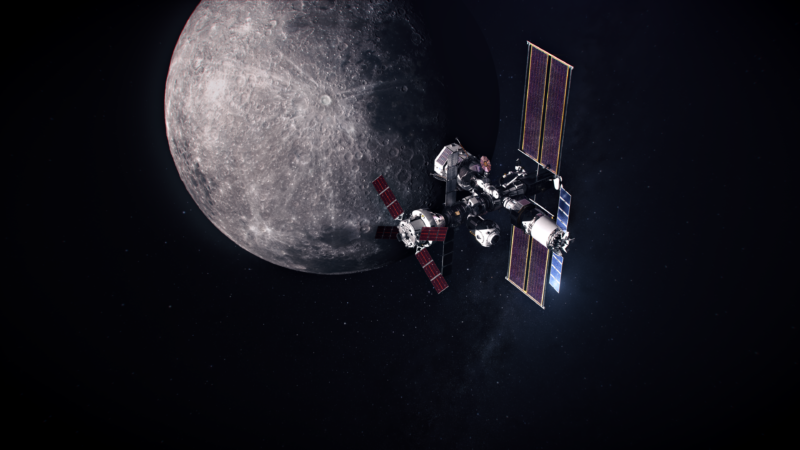

The Gateway—a research complex and lunar staging-post about one-sixth as large as the International Space Station (ISS)—has been in the works for several years. Its name has subtly changed on several occasions: initially known as the Deep Space Habitat (DSH), it later became the Deep Space Gateway (DSG), then the Lunar Orbital Platform-Gateway (LOP-G) and today it answers simply to “Gateway”.

As well as providing a jumping-off point for a sustained human presence on the surface of the Moon, it will support many investigations in planetary science, astrophysics, Earth observations, heliophysics, fundamental biology and human health and performance.

These include a pair of miniature “weather stations”—NASA’s Heliophysics Environment and Radiation Measurement Experiment Suite (HERMES) and the European Radiation Sensors Array (ESRA), provided by the European Space Agency (ESA)—to investigate solar activity and the space weather environment at lunar distance.

All told, the 4,400-cubic-foot (125-cubic-meter) Gateway boasts a strong international flavor, with Canada having committed to build its robotic assets, Japan contributing several critical elements of its Environmental Control and Life Support System (ECLSS), batteries, thermal control and imaging systems and ESA providing habitation, refueling and communications capabilities.

Two years ago, in May 2019, NASA selected Maxar Technologies—formerly Space Systems/Loral (SS/L)—to build the Gateway’s Power and Propulsion Element (PPE), which then-Administrator Jim Bridenstine called “the cornerstone” of the effort to create a sustainable and reusable human presence “on and around the Moon”. A System Requirements Review (SRR) in October 2019 enabled its technical risks and functional and performance needs to be formally baselined.

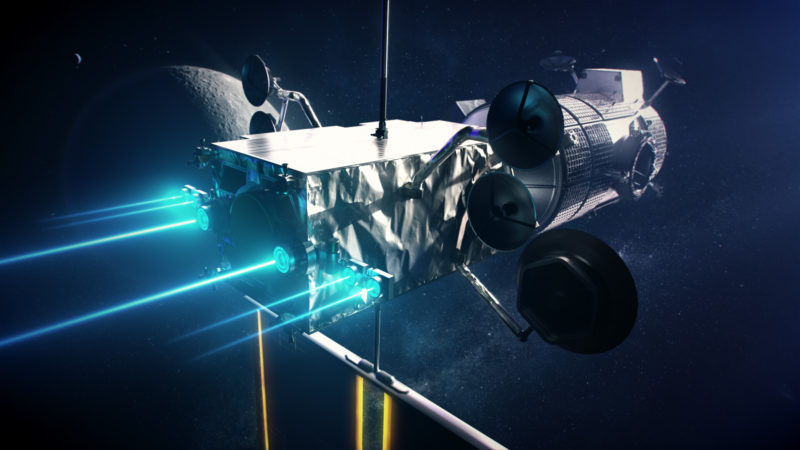

The 19,000-pound (8,600 kg) PPE is equipped with communications and maneuvering capabilities, together with high-powered, 50-kilowatt Solar Electric Propulsion (SEP) functionalities. Those SEP functionalities underwent an end-to-end series of hot-fire tests earlier this spring to validate subsystem performance and Maxar and NASA also wrapped up the Delta System Requirements Review (DSRR) and Tailored System Definition Review (TSDR) for PPE to ensure that its development remains on track.

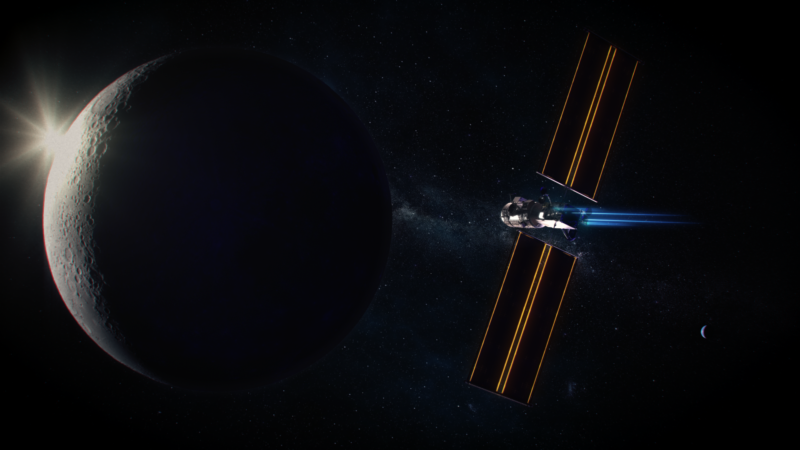

In June of 2020, NASA announced that the PPE would be pre-integrated and flown together with HALO atop a commercial booster, with launch initially moving from 2022 to no earlier than November 2023. This was expected to save NASA the expense of two rocket launches, as well as reducing the risks of sending a pair of spacecraft under their own steam to NRHO, then autonomously docking them together.

“The PPE and HALO module will be joined together by what is called an Inter-Element Adapter (IEA),” Northrop Grumman told AmericaSpace. “This structure provides the mechanical support for PPE for launch loads and provides for fluid and data-transfer across HALO/PPE interface.

The integration of the two modules will occur at the launch site.” Last February, SpaceX won the $331.8 million contract to deliver HALO/PPE on the outward leg of its voyage to lunar orbit, with launch atop a triple-barreled Falcon Heavy from Pad 39A at the Kennedy Space Center (KSC) in Florida initially targeted for No Earlier Than (NET) May 2024. This has now moved six months to the right.

As the PPE work progressed, Northrop Grumman was contracted last summer to guide HALO through its Preliminary Design Review (PDR). The module carries radial docking ports, Body-Mounted Radiators (BMRs), batteries and communication hardware and will furnish early Artemis crews with a functional pressurized volume capable of sustaining four people in NRHO for up to a month.

Northrop Grumman announced the successful conclusion of the PDR last November, with HALO expected to utilize mature technologies from its in-service Cygnus cargo ship in its design. Between September 2013 and last month, Cygnus has supported 15 fully successful missions to the ISS, with the recent NG-15 “Katherine Johnson” spacecraft remaining berthed at the sprawling orbital outpost for more than three months.

“Leveraging our success with our Cygnus spacecraft, Northrop Grumman is perfectly positioned to deliver the HALO module, a critical piece for NASA’s Artemis program and our journey to the Moon and beyond,” said Frank DeMauro, vice president and general manager for tactical space systems at Northrop Grumman.

“After recently completing a successful preliminary design review, we now look forward to completing the detailed design efforts and eventually bringing HALO to life in our Gilbert, Ariz., facility while also providing integration services for the final, combined vehicle before launch.”

That said, HALO is expected to remain in its exceptionally harsh location for many times longer than any Cygnus. “The HALO module is being designed for at least a 15-year life in the cislunar environment,” Northrop Grumman told us.

“To ensure the long-term operation of the module in this radiation environment, [it] incorporates redundancy in critical areas or systems and is designed to be maintained through the use of equipment spares and replacement parts available to the visiting crew. Some electronic components are being qualified and tested to ensure adequate radiation hardening is in place. There is no special shielding required for crews visiting the HALO module, due to the short visit durations of 30 days or less in this hostile environment.”

“By leveraging our active Cygnus production line, Northrop Grumman can uniquely provide an affordable and reliable HALO module, in the timeframe needed to support NASA’s Artemis Program,” said Steve Krein, vice president of civil and commercial satellites at Northrop Grumman. “Our team looks forward to continuing our collaboration with NASA in order to overcome the technical challenges associated with the harsh radiation and thermal environment of lunar space, as well as the unique challenge of hosting visiting crews for extended durations in this environment.”

Under the terms of the $935 million contract signed Friday, the company and its industrial partners will work towards the Critical Design Review (CDR) phase early next year and delivery of HALO to the Kennedy Space Center (KSC) in Florida for launch. According to comments provided by Northrop Grumman to AmericaSpace earlier this year, Thales Alenia Space Italy (TAS-I) expects to complete manufacturing of the welded primary-structure pressure shell of HALO by the end of 2021.

“Overall length of the pressure shell alone is about 23 feet (7 meters), while the complete HALO with interfacing structures and docking system is almost 29.5 feet (9 meters),” Northrop Grumman told us. “The diameter of the pressure shell is the same as Cygnus: about 10 feet (3 meters). Overall HALO mass is dependent on the final internal layout configuration and launch vehicle lift capability and is expected to be in the range of 17,600 pounds (8,000 kg) to 22,000 pounds (10,000 kg).”

Current plans are for Northrop Grumman to take delivery of HALO’s primary structure from TAS-I in the fall of 2022. “Our integration and verification work will include the final Go/No-Go checks prior to launch, as well as the support of the initialization of systems required to bring the module online, once in orbit,” Northrop Grumman told us. “Once the module is fully online, the real work to establish the evolution of the Gateway station can begin with NASA’s partners for lunar exploration.”