Only days after the arrival of the ten Solid Rocket Booster (SRB) segments for Artemis-1, NASA has awarded a $49.5 million letter contract authorizing Northrop Grumman Corp. to order long-lead-time items for six future missions of the Space Launch System (SLS). The super-heavylift booster—tasked with delivering the first humans to the Moon’s south pole by 2024—is currently slated to make its maiden voyage late next year. Its giant core stage is powered by a quartet of shuttle-heritage RS-25 engines, but 75 percent of its liftoff thrust will come from a pair of five-segment SRBs. The award is the first step in cementing plans for SLS missions throughout the remainder of the current decade.

Under the terms of the 150-day letter contract, Northrop Grumman will be able to make purchases as the details of the full Boosters Production and Operations Contract evolve over the next few months. The full definitized contract extends through the end of December 2030. “This initial step ensures that NASA can build the boosters needed for future Space Launch System rockets that will be needed for the Artemis missions to explore the Moon,” said John Honeycutt, SLS program manager at NASA’s Marshall Space Flight Center (MSFC) in Huntsville, Ala. “The letter contract allows us to buy long-lead materials in time for manufacturing boosters for the fourth flight.”

Each 177-foot-long (53.9-meter) booster comprises five segments—significantly larger and more capable than the four-segment SRBs used during the Space Shuttle program—and will provide the lion’s share of the impulse as SLS departs historic Pad 39B at the Kennedy Space Center (KSC) in Florida for the first time in the fall of 2021. And by leveraging the success and flight-proven design of the original SRB, which flew 270 times between April 1981 and July 2011 to boost 135 shuttle crews off the launch pad, reliability has been maintained and manufacturing costs have been lowered.

As detailed previously by AmericaSpace, the five-segment SRB was briefly considered for the shuttle program in the late 1990s as a means of eliminating two hairy ascent abort modes, affording greater safety in the event of a Space Shuttle Main Engine (SSME) failure and pushing the payload-to-orbit capability up by almost a third to nearly 60,000 pounds (27,200 kg).

And the boosters—which boasted a unique “center” segment, in addition to their four standard segments—would punch out a total of 3.6 million pounds (1.6 million kg) of thrust, a 20-percent performance hike over the standard shuttle SRBs.

The five-segment booster was later considered for the Ares V rocket and, after its cancelation in 2010, as the primary muscle for SLS. The first of ten segments for the giant rocket’s maiden mission was completed on 14 February 2017 and the last on 5 December 2017. Last month, all ten segments for Artemis-1 were transported by rail from Northrop Grumman’s facility in Promontory, Utah, to the Kennedy Space Center in Florida, where they were transferred to the Rotation, Processing and Surge Facility (RPSF) for storage.

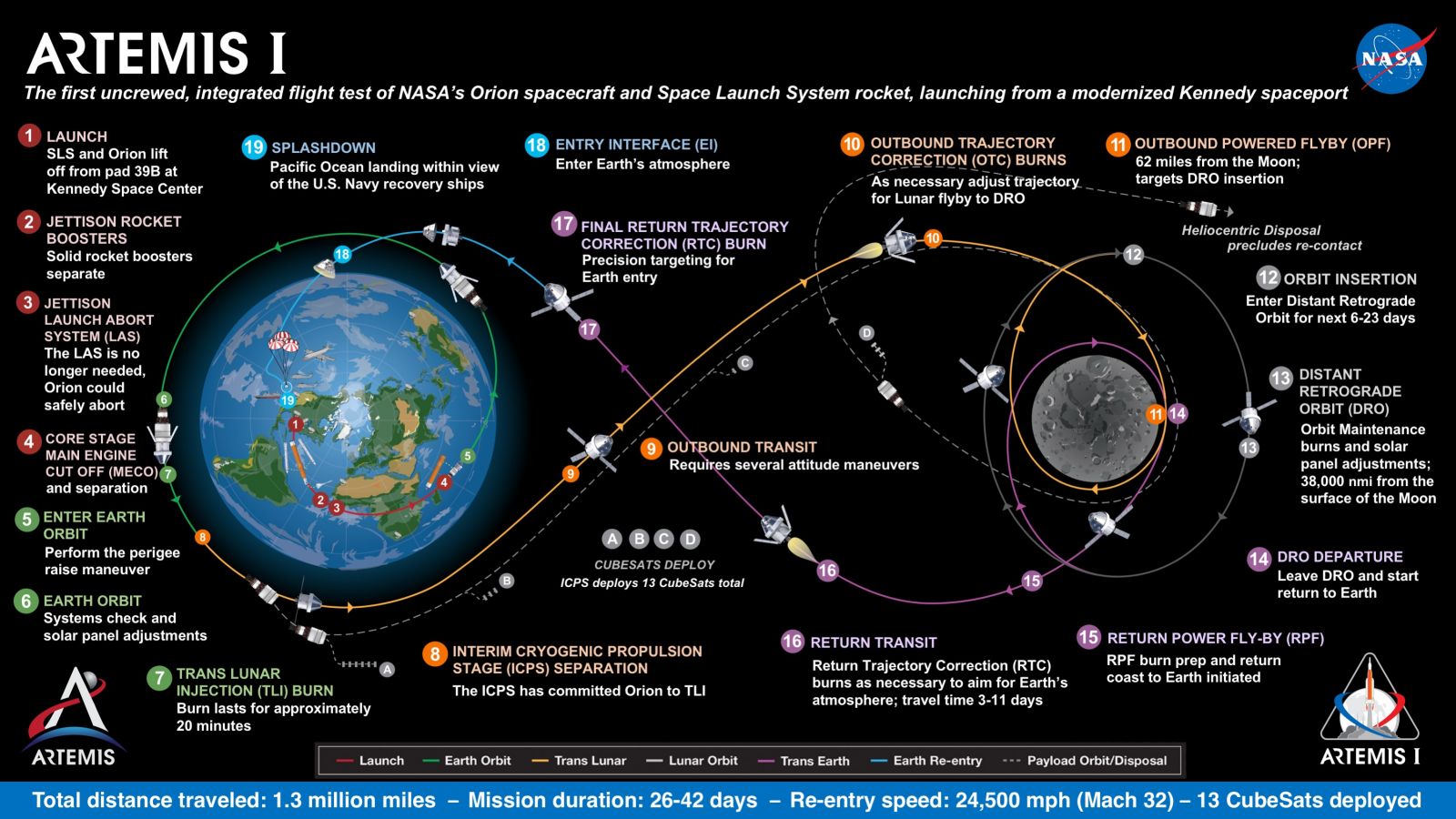

With Artemis-1 planned as an uncrewed voyage around the Moon, it will be Artemis-2 in 2023 which will see humans cross the cislunar gulf to approach our closest celestial neighbor for the first time in over five decades. And in 2024, Artemis-3 is expected to see the first astronauts walk on the Moon since Apollo 17 Commander Gene Cernan left his bootprints in the dust of Taurus-Littrow in December 1972.

Booster segments for Artemis-2 and Artemis-3 are already well into production. All ten segments for Artemis-2 are complete, with six segments for Artemis-3 ready. “We plan to complete casting (filling with propellant) the tenth Artemis-3 segment this October and all ten segments would then be completed and through final assembly by April,” Northrop Grumman’s Kay Anderson told AmericaSpace. “We will transport Artemis-2 and Artemis-3 segments to KSC upon NASA’s request, generally a year prior to launch.”

Yesterday’s letter contract allows Northrop Grumman to focus on essential purchases of long-lead-time items for Artemis-4 through Artemis-9, which, although launch dates remain somewhat fuzzy at present, are envisaged to occur at yearly intervals from 2025 until 2030. “Long-lead-time items would include such items as propellant ingredients, insulation, cables, nozzle bolts and hardware and carbon cloth,” Ms. Anderson explained.

“Motor propellant and insulation materials…can take as long as 18 months to obtain,” said Tracy McMahan of the Marshall Space Flight Center, in comments provided to AmericaSpace. “In order to be able to proceed into manufacturing without major gaps in production once the major contract is in place, it is necessary to order these materials early, before the entire effort is negotiated and definitized.”

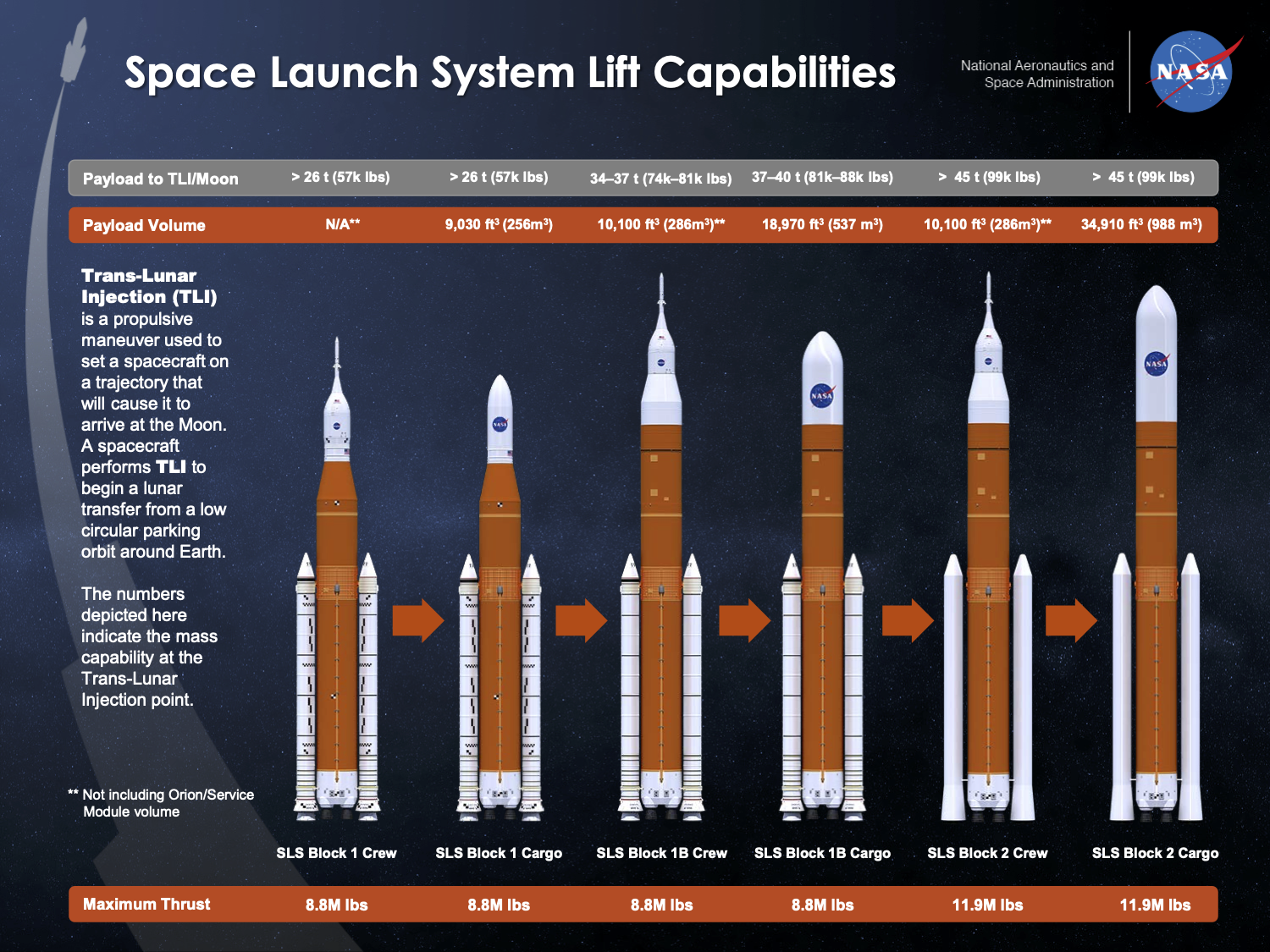

With all eyes on Artemis-3 as the first visit by humans to the surface of the Moon since the Apollo era, the follow-on missions encompassed in yesterday’s letter contract will expand the scope of exploration and begin the assembly of the lunar-orbiting Gateway. And whereas the first three Artemis missions will utilize the giant SLS in its “Block I” configuration—capable of boosting up to 57,000 pounds (26,000 kg) to the Moon—it is anticipated that subsequent flights will employ the more powerful Block IB and Block 2.

“It is planned that Artemis 4-8 will be Block IB and Artemis-9 will be Block 2,” Ms. Anderson told us. “We have a ground test planned for this August that will qualify propellant ingredients from new suppliers, but that is the only planned modification for this set of boosters.”

“The boosters will remain essentially the same for the first eight flights and are not affected by the vehicle’s upgrade to the Block IB configuration,” added Ms. McMahan. “However, after the eighth flight, the heritage boosters will no longer be available and they will be replaced by a new, composite case design that will fly on the ninth flight.”

“We operate under the principle of continuous improvement, thus any lessons learned during processing will be adapted if beneficial,” she continued. “We do follow, of course, a standard operating procedure to ensure the work is accomplished precisely as it should be. Our current plan is to cast one booster segment per month for the duration.”

FOLLOW AmericaSpace on Facebook and Twitter!

Missions » SLS »