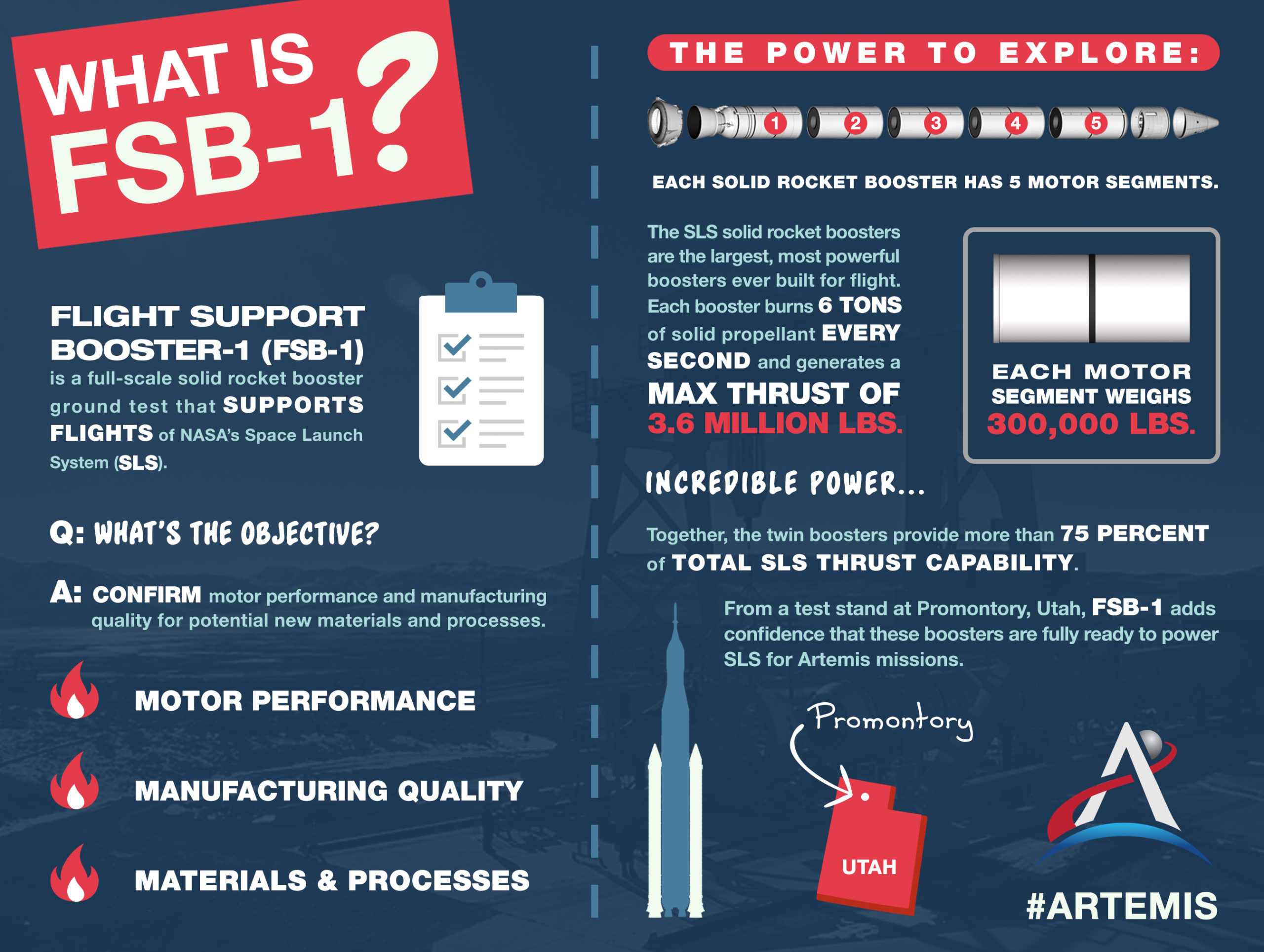

Next year’s targeted launch of Artemis-1 will take another step forward tomorrow (Wednesday, 2 September), when Northrop Grumman Corp. test-fires the Flight Support Booster (FSB)-1 at its facility in Promontory, Utah. The full-scale booster is a close analog for one of the twin five-segment Solid Rocket Boosters (SRBs) that will power the inaugural Space Launch System (SLS) off historic Pad 39B at the Kennedy Space Center (KSC) in Florida at some point late in 2021.

Coming on the heels of a pair of qualification-motor test-firings, FSB-1 is expected to significantly contribute to engineers’ understanding of motor performance and manufacturing quality of new booster materials and processes.

The FSB-1 test-firing is scheduled to occur at 12:40 p.m. local time (2:40 p.m. EDT) and will run for just over two minutes, the full duration anticipated for the twin SRBs on an actual SLS mission. It is expected to help evaluate potential new materials, processes and improvements for the boosters as NASA and Northrop Grumman look past Artemis-3—currently expected to return the first humans to the lunar surface since Apollo 17 in December 1972—and focus on the deep-space missions of exploration beyond. Earlier this summer, NASA issued a letter contract to Northrop Grumman to begin ordering long-lead-time items for Artemis missions 4-9, which are tentatively slated to fly in the 2025-2030 timeframe.

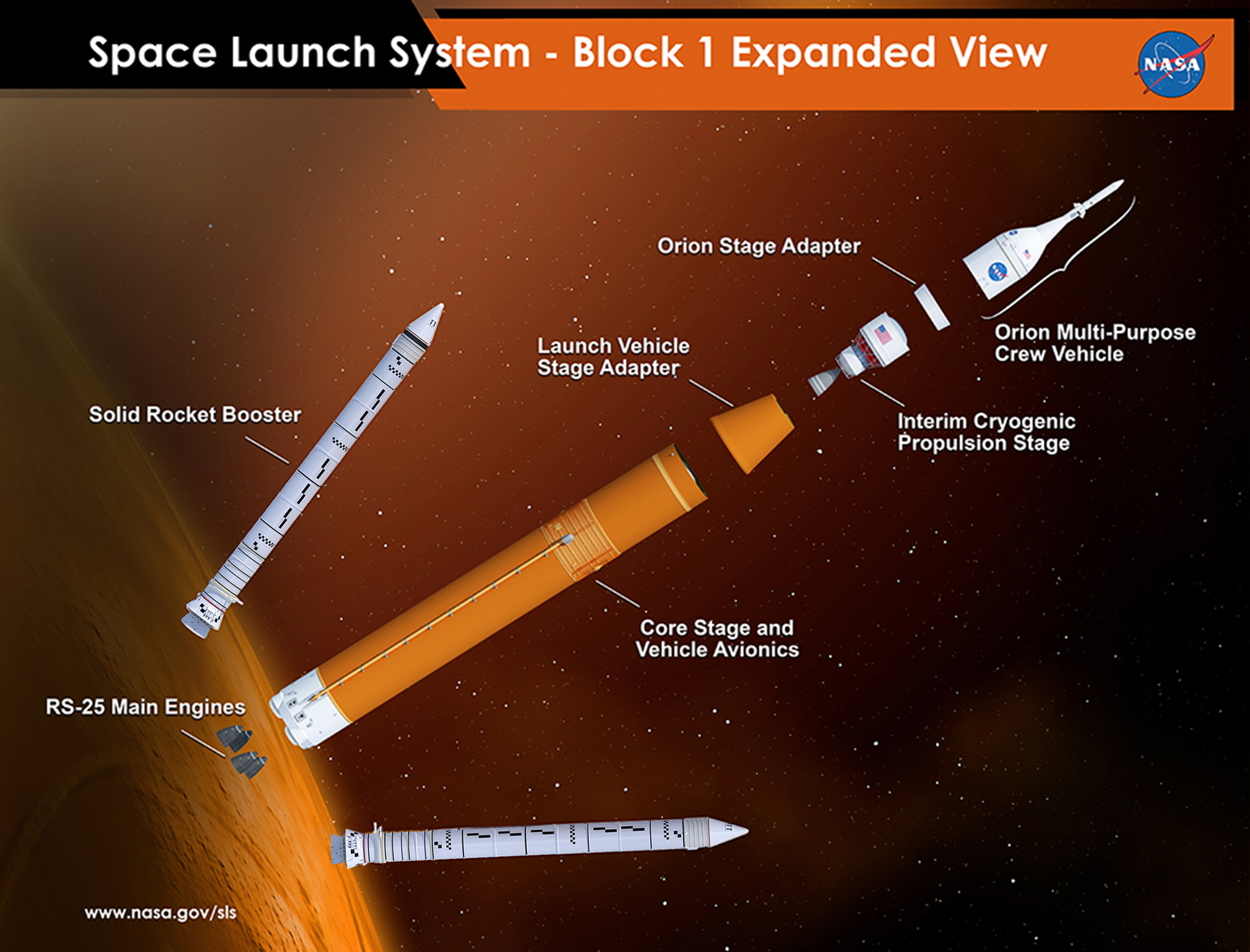

Whereas the twin SRBs used during the 30-year Space Shuttle Program each incorporated four 300,000-pound (135,000 kg) segments—designated Forward, Center-Forward, Center-Aft and Aft, together with the nose-cone hardware, Solid Rocket Motors (SRMs) and aft skirt assemblies—those of the SLS benefit from an additional “middle” segment, known as Center-Center. This increases the length of each booster from 149 feet (45.5 meters) in its shuttle incarnation to 177 feet (53.9 meters) for SLS and affords a corresponding increase in thrust from 2.8 million pounds (1.3 million kg) to a little over 3.6 million pounds (1.6 million kg). Burning together for the first two minutes of each SLS launch, the two boosters will thus generate in excess of 7.2 million pounds (3.2 million kg) of propulsive yield, more than 75 percent of the super-heavylift rocket’s total thrust.

According to Northrop Grumman, the first piece of FSB-1 major hardware, the Forward Segment, was installed into the test stand in mid-April and the final piece, the aft exit cone, was set in place in mid-July. Measuring 154 feet (47 meters) in length and 12.7 feet (3.9 meters) in diameter, FSB-1 reportedly weighs 1.6 million pounds (725,700 kg). During the course of the two-minute test, more than 302 data channels will be monitored, as Northrop Grumman and NASA personnel work methodically through a group of primary and secondary objectives.

Of principal significance is the qualification of additional suppliers of the boosters’ propellant ingredients.

“The aluminum powder manufacturer moved its facility, bringing the need to obtain from a new supplier, which was the initial purpose of FSB-1,” Northrop Grumman’s Kay Anderson told AmericaSpace. “Once the test was established, more objectives were added. FSB-1 will qualify various propellant ingredients for both supplier obsolescence issues and to have multiple qualified resources. Propellant ingredients are the same as shuttle and were modified slightly to meet the performance requirements for the longer rocket motor and new vehicle.”

FSB-1 will evaluate all ballistic parameters and performance, the ignition sequence interval, pressure and thrust build-up rates, as well as performance tolerances and limits. Additional tests include an all-up demonstration of the SRM nozzle forward exit cone housing and measuring the nozzle’s load-response to the sound-suppression water system during the ignition sequence. After the completion of FSB-1, the booster will be transported to Northrop Grumman’s Clearfield Facility for post-test inspection, disassembly and refurbishment.

Five-segment SRBs with modified nozzles were considered during the shuttle program, as a means of improving safety, payload-to-orbit performance and reducing system costs. In particular, it was expected to eliminate the shuttle’s hairy Return to Launch Site (RTLS) and Transoceanic Abort Landing (TAL) abort modes and provide greater capacity for an Abort Once Around (AOA) in the event of a Space Shuttle Main Engine (SSME) failure shortly after liftoff. And it would boost the shuttle’s payload-to-orbit capacity by almost 20,000 pounds (9,000 kg) to 60,000 pounds (27,200 kg). Shelved after the February 2003 loss of Columbia, the five-segment SRB was later revived (for a time) in support of NASA’s Constellation Program and Ares V super-heavylift rocket.

With the cancelation of Constellation and Ares V by the Obama Administration in 2010, new life was breathed into the five-segment SRB when NASA unveiled the SLS concept in September 2011.

A two-minute Qualification Motor (QM)-1 test firing took place in March 2015 to evaluate booster performance at peak operating temperatures of 32 degrees Celsius (90 degrees Fahrenheit), the expected “high-end” of its accepted propellant temperature range. This was followed by QM-2 in June 2016, which repeated the exercise at 4.5 degrees Celsius (40 degrees Fahrenheit), the “low-end” of the temperature range.

Earlier this summer, the ten SRB segments for Artemis-1—the first uncrewed test flight of the combined SLS/Orion vehicle—were delivered by rail from Promontory, Utah, to the Kennedy Space Center (KSC) in Florida for processing.

The purpose of the FSB-1 test is to permit engineers to evaluate potential new materials, processes and improvements for the boosters destined to power “downstream” missions, beyond Artemis-3, which is currently projected to deliver the first humans to the lunar surface since Apollo 17. Northrop Grumman previously told AmericaSpace that all ten booster segments for Artemis-2 and six of the segments for Artemis-3 are complete. “We plan to complete casting the tenth Artemis-3 segment this October and all ten segments would then be completed and through final assembly by April [2021],” Ms. Anderson advised us in an earlier communication. “We will transport Artemis-2 and Artemis-3 segments to KSC upon NASA’s request, generally a year prior to launch.”

In the meantime, in June NASA awarded Northrop Grumman a $49.5 million letter contract, authorizing the organization to begin ordering long-lead-time items for the boosters for Artemis missions 4-9, currently targeted to launch later this decade. According to Ms. Anderson, those items include propellant ingredients, insulation, cables, nozzle bolts and hardware and carbon cloth.

“Motor propellant and insulation materials…can take as long as 18 months to obtain,” said Tracy McMahan of NASA’s Marshall Space Flight Center (MSFC) in Huntsville, Ala., in comments previously provided to AmericaSpace. “In order to be able to proceed into manufacturing without major gaps in production once the major contract is in place, it is necessary to order these materials early, before the entire effort is negotiated and definitized.”

.

.

FOLLOW AmericaSpace on Facebook and Twitter!

.

.