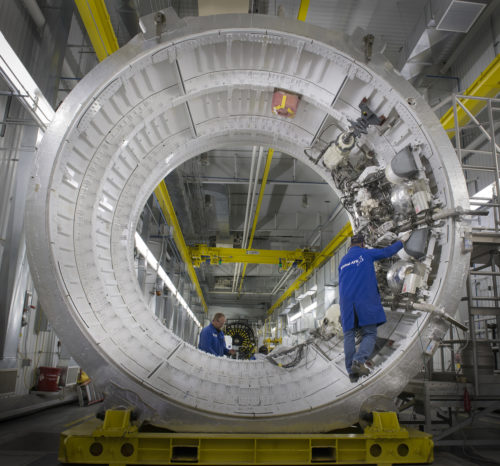

The solid rocket booster that will propel NASA’s skyscraper-size, 300-plus-foot-tall Space Launch System (SLS) rocket and its Orion spacecraft in the coming years took a huge step forward in its development on March 11, 2015, unleashing its fury on a barren mountainside at Orbital ATK’s test stand in Promontory, Utah, for the Qualification Motor-1 test fire (QM-1). The 154-foot-long booster, the largest of its kind in the world, ignited to verify its performance at 90 degrees, the highest end of the booster’s accepted propellant temperature range and the temperature the SLS can expect to encounter on a regular basis at its Florida launch site on Kennedy Space Center (KSC) Launch Complex 39B.

Detailed inspections of the now disassembled booster have been ongoing for several months since, with all the data collected confirming the QM-1 test as a resounding success. More than 500 instrumentation channels were used to help evaluate over 100 defined test objectives, and now work is underway building a second booster for another test fire, Qualification Motor-2 (QM-2), which is scheduled to take place in spring 2016 on the same test stand.

A cold-temperature test, at a target of 40 degrees Fahrenheit, the low end of the propellant temperature range, is planned for QM-2 before the hardware testing to support qualification of the boosters for flight will be complete, at which point Orbital ATK will then be ready to proceed toward the first flight of the SLS, an uncrewed mission to validate the entire integrated system, currently scheduled to fly on the Exploration Mission-1 (EM-1) in November 2018.

“We are making significant progress in preparation for the second qualification test,” says Bruce Tiller, deputy manager of the SLS Boosters Office at NASA’s Marshall Space Flight Center in Huntsville, Ala. Marshall manages the SLS Program for the agency. “The completion of these qualification tests is crucial in getting the boosters certified for the first two flights of SLS and staying the course for the journey to Mars.”

Earlier this month, on Sept. 22, engineers successfully tested the booster thrust vector control and avionics systems during an off-motor hot-fire test to simulate the test cycle that will be used in the QM-2 test fire next year, which will closely resemble flight conditions. The thrust vector control and avionics system successfully provided the required command and control of the motor nozzle position during the QM-1 test fire, and the same is expected of QM-2.

The thrust vector control system steers the rocket nozzle based on commands passed through the booster avionics system made up of hardware, software, and operating systems that will communicate with the SLS avionics system and ground operations. The avionics also will control booster operations, like motor firing and separation motor ignition.

Four of the five segments of the giant booster have already been cast, and the final segment is scheduled to be cast in the coming days. Two of the cast segments have already undergone rigorous inspections as well, with the other two following suit over the next couple months.

“The rear and forward segments have successfully completed all non-destructive evaluation with no defect indications and are currently in final assembly,” says Fred Brasfield, Orbital ATK vice president for NASA programs. “The next major event for the rear segment will be installation of the nozzle, which is expected to happen in November.”

“Finding no defects in the segment insulation we’ve inspected so far is a huge accomplishment for our teams, and something that hasn’t been done on past NASA programs,” says Tiller. “That’s a testament to the work we’ve put in on refining our manufacturing processes and materials.”

Small voids were previously discovered prior to QM-1 between the propellant and outer casing of the booster’s aft segment, which demanded a lengthy investigation and trouble-shooting effort by Orbital ATK and NASA to determine root cause(s) and corrective actions before they could move forward with booster testing for QM-1 (which had been significantly delayed due to the issue).

With QM-1 there have been four fully developed, five-segment SRBs fired up on Orbital ATK’s Promontory, Utah, T-97 test stand since 2009, with the most recent prior to QM-1 having been conducted in 2011, and all performed fine. The first three tests, known as the Development Motor test series (DM-1, DM-2, and DM-3), helped engineers measure the new SRB’s performance at low temperature, verify design requirements of new materials in the motor joints, and gather performance data about upgrades made to the booster since the space shuttle program.

The five-segment SLS boosters will burn for the same amount of time as the old shuttle boosters—two minutes—but they will provide 20 percent more power, while also providing more than 75 percent of the thrust needed for the rocket to escape the gravitational pull of the Earth.

“Ground tests are very important – we strongly believe in testing before flight to ensure lessons-learned occur on the ground and not during a mission,” said Charlie Precourt, Vice President and General Manager of Orbital ATK’s Propulsion Systems Division and four-time space shuttle astronaut. “With each test we have learned things that enable us to modify the configuration to best meet the needs for the upcoming first flight.”

The five-segment solid rocket booster has been in development for years, having been initially designed to launch NASA’s Ares rockets for the agency’s cancelled Constellation program. The booster is similar to the four-segment SRBs that helped launch NASA’s now retired space shuttle fleet, but it’s larger and incorporates several upgrades and improvements.

Although the boosters themselves will provide 75 percent of the power needed to break Earth’s hold, the SLS will still employ four engines of its own—former (upgraded) liquid-fueled space shuttle RS-25 engines—which are currently at NASA’s Stennis Space Center in Mississippi undergoing their own series of tests.

VIDEO: QM-1 Test Fire for NASA’s SLS, March 2015

Be sure to “Like” AmericaSpace on Facebook and follow us on Twitter: @AmericaSpace

Missions » SLS » Missions » SLS » QM-2 »

The article’s quote by “Bruce Tiller, deputy manager of the SLS Boosters Office at NASA’s Marshall Space Flight Center in Huntsville, Ala”,”The completion of these qualification tests is crucial in getting the boosters certified for the first two flights of SLS and staying the course for the journey to Mars” leads one to consider exactly where and what is included in the very vague “course for the journey to Mars”.

Perhaps NASA’s scientific “course for the journey to Mars” should include some real science and technology instead of endlessly repeated empty political rhetoric.

Consider the September 17, 2015 article “Some Apollo Moon Samples ‘Crumbling to Dust'” by Mike Wall, where a comment by Bonnie Cooper at Hanyang University in South Korea is noted, “To store future samples so that they are not contaminated by Earth’s atmosphere, we need a facility like the International Space Station (with samples stored outside the pressurized area and examined robotically) or a similar facility on the moon”.

Yikes! Has anyone told NASA’s leadership that Bonnie Cooper thinks the Moon might be scientifically useful on NASA’s unfunded and always zigzagging “course for the journey to Mars”?

Oddly enough, NASA’s leadership appears to believe in reciting vague and highly partisan Mars rhetoric and not in science and technology or following and fully implementing the NASA Authorization Act of 2010 (PL 111–267).

Nonetheless, it is very good to see real progress on the boosters for future SLS/Orion missions to the Moon.

Nice article! Thank you Mike Killian!