Early on 20 May 1996, NASA astronaut Mario Runco, Jr., grappled SPARTAN-207—a small, free-flying spacecraft, equipped with a very unique experiment—and lifted it from Shuttle Endeavour’s payload bay with the Canadian-built Remote Manipulator System (RMS) mechanical arm. Together with his five crewmates, Runco had launched just 24 hours earlier, kicking off the 10-day STS-77 mission. And on STS-77, the frequent-flying SPARTAN would undertake its most ambitious exercise yet. Runco released the satellite on time at 7:29 a.m. EDT, into orbital darkness, after which Commander John Casper maneuvered Endeavour to a distance of about 820 feet (250 meters).

Once there, Casper held his ship’s position for about an hour, before conducting a partial flyaround, to a point directly “above” the satellite. Next, he began an 80-minute period of station-keeping to observe a quite remarkable experiment: an experiment with potentially enormous benefits for a range of applications, from space radar to mobile communications, from astronomy to Earth observations, and from environmental research to the analysis of soil moisture and salinity. In fact, STS-77—which was in orbit 20 years ago, this week—set the space shuttle’s myriad capabilities to work and served as a critical pathfinder for future research aboard the International Space Station (ISS).

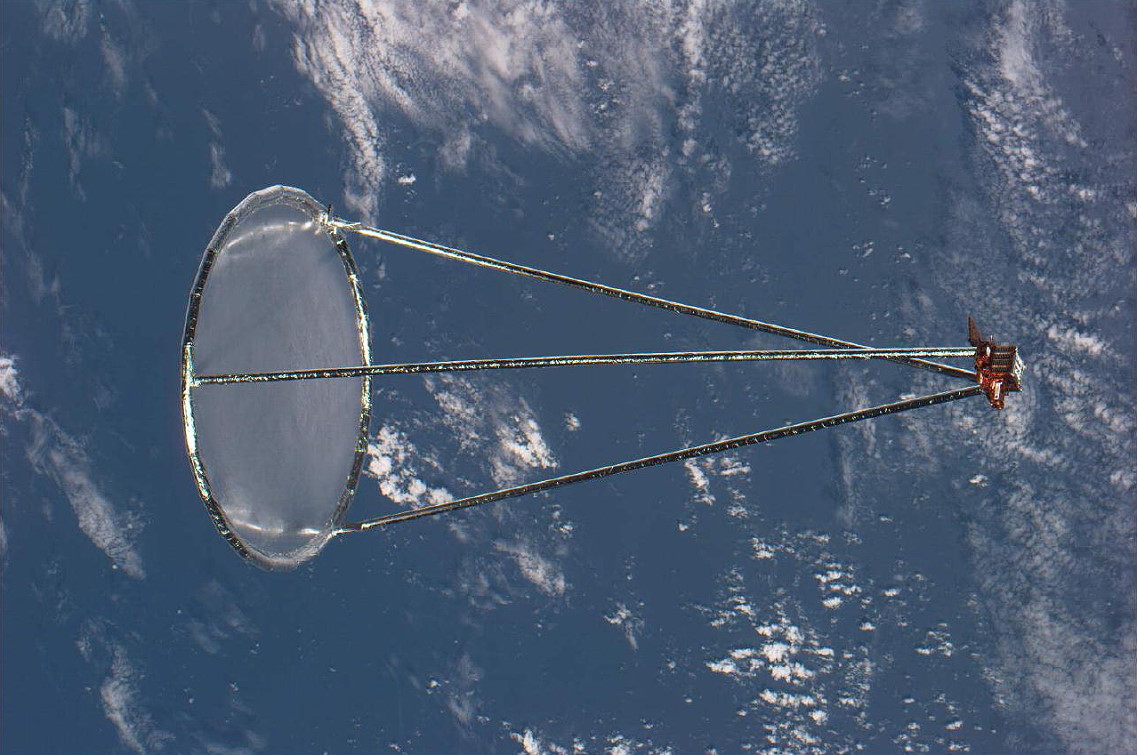

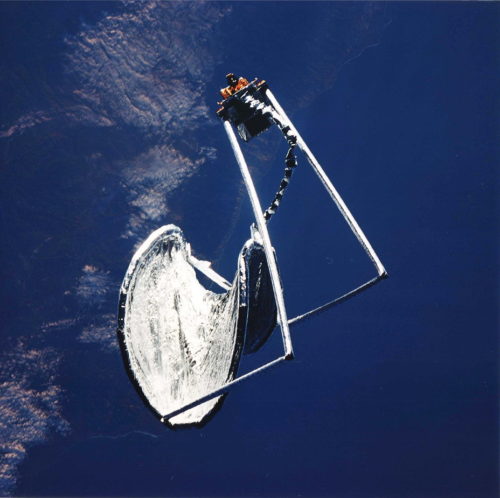

Two hours after Runco released SPARTAN-207, the Inflatable Antenna Experiment (IAE) got underway. Designed and built by L’Garde, Inc., a small aerospace company, based in Tustin, Calif., together with NASA’s Jet Propulsion Laboratory (JPL) of Pasadena, Calif., it sought to inflate a 46-foot-wide (14-meter) Mylar antenna dish, at the apex of three deployable struts, as part of an investigation into how large, expandable structures behaved and functioned in the microgravity environment. Since 1971, L’Garde had pioneered the construction of thin-skinned, multi-task balloons and its products included a decoy missile for the Department of Defense.

It had long been recognized that the mass and stowed volume of inflatable space components was significantly less than an equivalent solid structure and that this carried the potential to reduce by 10-100 times the cost of future missions. In 1988, L’Garde began working on the IAE, and, according to the company’s founder and vice president, Alan Hirasuna, the $14 million cost of this inflatable antenna was a mere fraction of the $200 million to build a similar-sized antenna with more conventional materials. Moreover, its compactness and 130-pound (60-kg) weight meant that it could be carried aboard much smaller launch vehicles.

At 9:38 a.m. EDT, as six pairs of astronaut eyes and a battery of still, video, and motion-picture camera equipment aboard Endeavour looked on, SPARTAN-207 commanded the deployment of IAE’s supporting tripod, each of whose neoprene-coated Kevlar limbs unfolded to 92 feet (28 meters). At their apex, a canister of pressurized nitrogen gas inflated the antenna, in just five minutes, to its full diameter of 46 feet (14 meters). With a silver reflective surface on its topside and a clear underside, the IAE was then observed and photographed over the following 90 minutes by the STS-77 crew and illuminated by an array of lights aboard SPARTAN-207 to precisely measure its smoothness. The antenna was then jettisoned, steadily moving “below” and “ahead” of the satellite, as Casper executed a Reaction Control System (RCS) thruster firing to maneuver Endeavour “above” and “behind” it. They would maintain a distance of 55-70 miles (90-110 km) from SPARTAN-207—which also carried a number of other experiments, including a new solid-state recorder and advanced integrated circuits—for the next two days.

By the evening of 20 May, a few hours after deployment, the discarded IAE was being tracked at a distance of more than 115 miles (185 km) “ahead” and “below” the shuttle and, judging from its large size and relatively low weight, trajectory planners expected it to re-enter Earth’s atmosphere within 17-24 hours. As it happened, IAE finally re-entered early on 22 May, the same day that Casper and his crewmates re-rendezvoused with SPARTAN-207 to begin retrieval operations.

Awakened from their slumbers that morning to the sound of Fifth Dimension’s song Up, Up and Away, in honor of their completed experiment, the astronauts wasted no time preparing their equipment for the rendezvous. In a similar manner to the approach procedures followed by several earlier shuttle crews, a Terminal Initiation (TI) burn of Endeavour’s RCS thrusters kicked off the final approach and Casper guided his ship to just 35 feet (10 meters) from SPARTAN-207, whereupon astronaut Marc Garneau—who in October 1984 had become the first Canadian in space—extended the RMS and grappled the satellite at 10:53 a.m. EDT. As the satellite hung on the end of the arm, the crew performed a video and photographic survey, before it was berthed in the payload bay.

With the successful retrieval of SPARTAN-207, the shuttle’s mission was barely a quarter complete, but its wide range of scientific and technological experiments were well underway. Flying for the fourth time as a research facility on STS-77, the commercial Spacehab was not dissimilar in appearance to the European Space Agency’s (ESA) Spacelab module, but with several key differences: It was smaller, consuming just a quarter of the payload bay, and it was designed and built not by governments, but by private enterprise. It also differed from Spacelab in overall physical shape; it was cylindrical, but with a flat roof. When the module rose from Earth for the first time on STS-57 in June 1993, it marked the realization of a decade-long dream for aerospace engineer Bob Citron, who founded Spacehab in 1983 and incorporated it the following year.

“People often ask me why I started Spacehab,” Citron recalled years later, “and my response usually goes something like this: It took a small group of wide-eyed dreamers and determined space enthusiasts who believed we could pull it off. We didn’t have a clue about the enormous problems we would encounter and the nearly insurmountable technical, financial and institutional roadblocks that would stand in our way. Nobody had done anything like this before.” The primary goal of Citron, who died in January 2012, was to create the world’s first privately funded company to support human space missions, using the payload bay of the shuttle as a carrier of commercial pressurized research modules.

The need for such provision was self-evident. In the shuttle’s pre-Challenger heyday, many missions were planned each year and a primary thrust of the Reagan Administration’s 1983 space policy was for the commercial exploitation of the microgravity environment. Middeck lockers were being used to carry out experiments in crystal growth and pharmaceutical research, but the limited volume meant that their commercial viability was restricted. The Spacehab module, accessed via a tunnel connected to the middeck airlock hatch, measured 9.2 feet (2.8 meters) long, 11.2 feet (3.4 meters) high, and 13.4 feet (4.1 meters) across the width of the payload bay and could increase the shuttle’s pressurized envelope by almost 1,100 cubic feet (31 cubic meters), more than tripling the available working and storage space. The module, which weighed approximately 9,480 pounds (4,300 kg), could house a total payload of more than 2,870 pounds (1,300 kg), including up to 61 lockers and two large racks.

After incorporating Spacehab in 1984, Citron admitted that the company was “on the verge of failure on a number of occasions during its first years,” until he brought in critical professional management personnel and “things started to happen” through negotiations with NASA, the Italian Alenia Spazio, and German MBB-Erno organizations, as well as Martin Marietta and McDonnell Douglas. By the end of 1985, only weeks before the Challenger tragedy, Spacehab was tentatively scheduled for its first flight in 1987 and a lease of $5 million per mission was quoted by Flight International. Early plans called for the assembly of three modules, but center-of-gravity issues gave NASA cause for concern and threatened to affect the placement of other cargo in the payload bay.

Ultimately, McDonnell Douglas was selected as the lead contractor and a decision was made to build two flight modules and an engineering test model. Other worries lingered, but in late 1986 Spacehab signed a Space System Development Agreement, in which NASA agreed to fly five inaugural missions. By October 1987, 42 requests had been received, with lockers priced at $300,000 for non-government users and $100,000 for government agencies and contractors. The concept was now growing from initial designs into reality. In September 1989, Patent No. 4,867,395 for a “Flat End-Cap Module for Space Transportation System” was awarded to Spacehab, Inc., by the U.S. Patent Office.

Hopes to fly the modules on very early post-Challenger missions received a rude awakening, however, and it was at least three years after the resumption of shuttle operations before a first flight could be realistically expected. According to NASA’s April 1988 schedule, Spacehab-1 was listed as a primary payload on STS-51 in June 1991. This schedule slipped and, at length, the first module was not unveiled until early 1992 at the custom-built Spacehab Payload Processing Facility (SPPF) at the Kennedy Space Center (KSC) in Florida. By this time, under the Commercial Middeck Augmentation Module procurement, initiated in February 1990 and formally signed the following December, NASA agreed to lease a total of 200 Spacehab lockers at a cost of $184.2 million. Over the coming years, the SPPF would host more than a hundred astronauts and cosmonauts, enabling them to train on real experiment hardware.

However, all was not smooth sailing for Spacehab, which supported three dedicated science missions between June 1993 and February 1995 and was embarking on its fourth “stand-alone” flight on STS-77. In the aftermath of the first flight, however, few contracts outside NASA materialized for the laboratory, in spite of aggressive efforts to market its capabilities. This was due to a number of factors, chiefly high Spacehab locker prices in the region of $925,000 and anticipated commercial prospects failing to materialize. “No commercial companies are ready yet to make an independent commitment to research,” said Rebecca Gray, Spacehab’s manager of government and public relations, in a Flight International interview in the fall of 1995, despite the company having delivered its services on time and on budget.

NASA’s contract was renegotiated to cover four missions, of which STS-77—whose module, though full, was dominated by NASA-funded experiments—was to be the last. “If NASA requires more flights of this nature,” Flight International continued, “it is likely only to be at a rate of about one flight a year and another contract will have to be negotiated.” The company had already signed a $54 million lease contract with NASA to utilize its modules for logistics on several missions to Russia’s Mir space station in 1996-1998. It also invested $15 million of its own capital to develop a “double” logistics module to be used “as a laboratory and a cargo carrier,” with the capacity to transport up to 6,000 pounds (2,720 kg) of payloads to Mir, as well as soft-stowage canvas bags for supplies. However, the option for more “stand-alone” research missions would be renegotiated and two would be flown: STS-95 in late 1998, which saw Project Mercury pioneer John Glenn return to space, and STS-107 in early 2003, the final voyage of Columbia.

More than 90 percent of the Spacehab-4 payloads were directly sponsored by NASA’s Office of Space Access and Technology (OSAT), through its Commercial Space Centers and their industrial partners, as well as by several of the agency’s field centers. Right from the outset, STS-77 was dedicated to opening the commercial frontier of space, with the Spacehab module hosting almost 3,000 pounds (1,400 kg) of equipment in 28 lockers, four soft stowage bags, and a pair of single racks to support around a dozen investigations in the fields of biotechnology, electronic materials, polymers, and agriculture. These included the Advanced Separation Process for Organic Materials (ADSEP) to demonstrate separation and purification technologies for potential medical and pharmaceutical applications, the Commercial Generic Bioprocessing Apparatus (CGBA) and Plant Generic Bioprocessing Apparatus (PGBA) to investigate the influence of microgravity on molecular, cellular, tissue, and small animals and plants—as well as studying compounds which might someday prove beneficial as chemotherapy and anti-malaria agents—and the Fluids Generic Bioprocessing Apparatus (FGBA) to explore the management of liquids in space.

The latter received corporate sponsorship from the Coca-Cola Company, which flew both Coke and Diet Coke aboard STS-77. The experiment, noted NASA, “will provide a testbed to determine if carbonated beverages can be produced from separately stored carbon dioxide, water and flavored syrups and determine if the resulting fluids can be made available for consumption without bubble nucleation and resulting foam formation.” If so, it was hoped that such experiments might lead to a better understanding of altered tastes in target populations, such as the elderly, and how future drinks could be tailored to increase hydration. International co-operation on STS-77 was underpinned by the presence of the Commercial Float Zone Furnace (CFZF), a joint effort between the respective space agencies of the United States, Canada, and Germany to produce large, ultra-pure compound semiconductor and mixed-oxide crystals of gallium arsenide and gallium antimonide for electronic devices and infrared detectors. Another payload, the Space Experiment Facility (SEF), used a furnace to produce through vapor-diffusion a series of crystals of mercurous chloride, which is considered a valuable electro-optical material of commercial interest, and to bond powdered metals through the liquid-phase sintering process, as part of efforts to design new composites for the machine tool industry.

STS-77 was shaping up to be not only an ambitious mission in space science and technology, but as an important demonstrator of the shuttle’s myriad capabilities as a research platform, as a satellite deployment and retrieval facility, and as full-up precursor for the kind of work which would someday become “routine” aboard the International Space Station (ISS). Indeed, three members of the STS-77 crew—Marc Garneau, Andy Thomas, and Dan Bursch—would help build the multi-national station in the coming years: Garneau would perform critical robotics work in support of the installation of its first set of power-producing solar arrays, whilst Thomas would spacewalk outside it and Bursch would be a member of one of its earliest long-duration crews.

The second part of this article will appear tomorrow.

Want to keep up-to-date with all things space? Be sure to “Like” AmericaSpace on Facebook and follow us on Twitter: @AmericaSpace

If you do this, you can potentially produce at least 4 short articles in just one hour.

When you think of purchasing the keywords, make sure that they are related to

the subject matter of the business. Ask question, present intriguing

statements, or challenge common beliefs.